Table of Contents

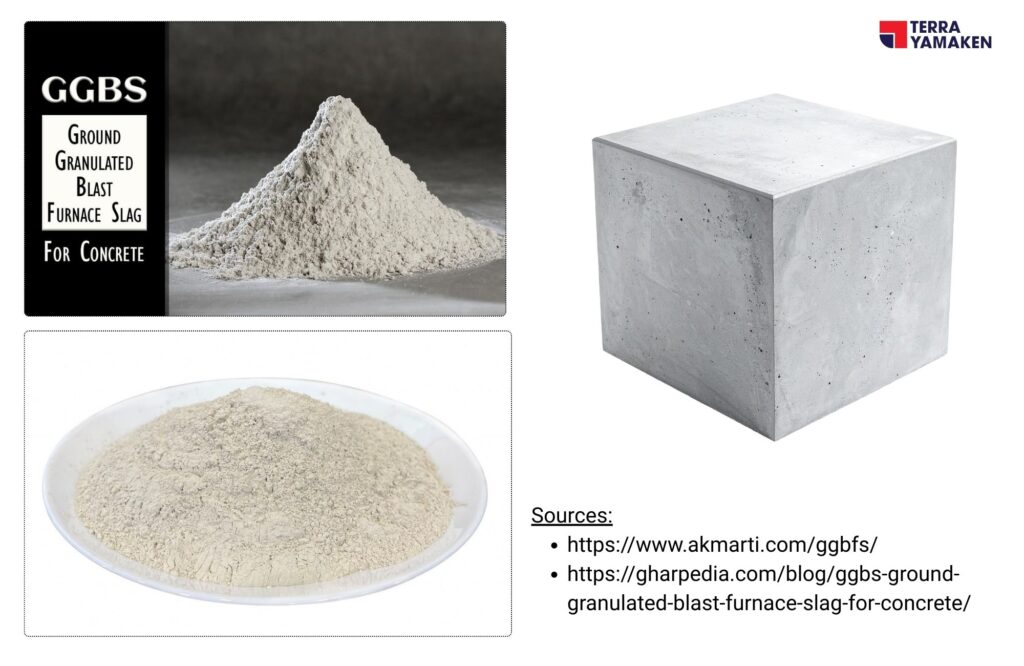

ToggleIn concrete construction, controlling the air content is a critical factor in ensuring the structural integrity and durability of the finished element. Air content refers to the amount of entrained or entrapped air introduced into the concrete mix during batching, which directly affects workability, compressive strength, and material uniformity. Additionally, the occurrence of surface voids—commonly known as bugholes—formed on the concrete surface in contact with formwork, must be strictly managed to maintain both aesthetic quality and surface durability. Clearly distinguishing between air content and bugholes enables construction engineers to implement appropriate placement and compaction techniques, thereby optimizing concrete quality and enhancing long-term performance in real-world applications.

Air Content in Fresh Concrete

According to TCVN 3111:2022, air content is defined as the volume of air entrained into the concrete mix during the mixing process. This standard outlines the method for determining the air content in concrete mixtures, applicable to concrete and mortar made with dense aggregates. It does not apply to lightweight or highly porous aggregates, and is only valid for mixes with a slump of 10 mm or greater.

Depending on the structural application, the required air content is specified by the technical requirements of each project. However, to ensure consistency and maintain the essential mechanical properties of conventional heavy concrete, TCVN 8826:2011 mandates that the air content in fresh concrete using chemical admixtures must not exceed 2%.

Controlling air content is crucial because:

- Strength: Excessive air reduces compressive strength and load-bearing capacity.

- Uniformity: Ensures a homogeneous concrete structure without large voids caused by air pockets.

- Aesthetics: Excess air can negatively affect the surface finish and appearance of the concrete.

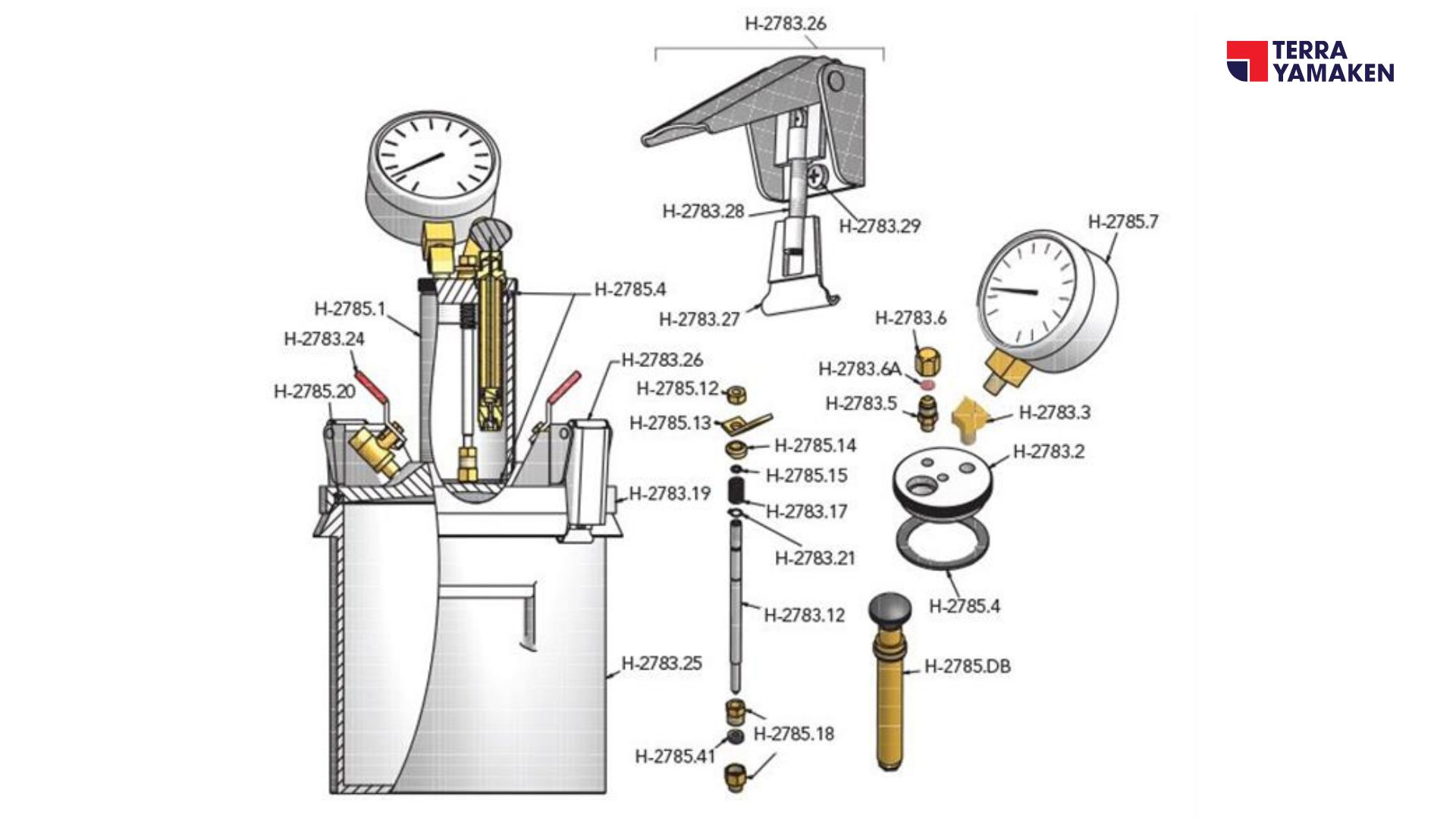

Figure 1 – Air Content Testing Apparatus Used to Measure Entrained Air in Concrete [1]

Figure 1 – Air Content Testing Apparatus Used to Measure Entrained Air in Concrete [1]

Bugholes on Concrete Surfaces Adjacent to Formwork

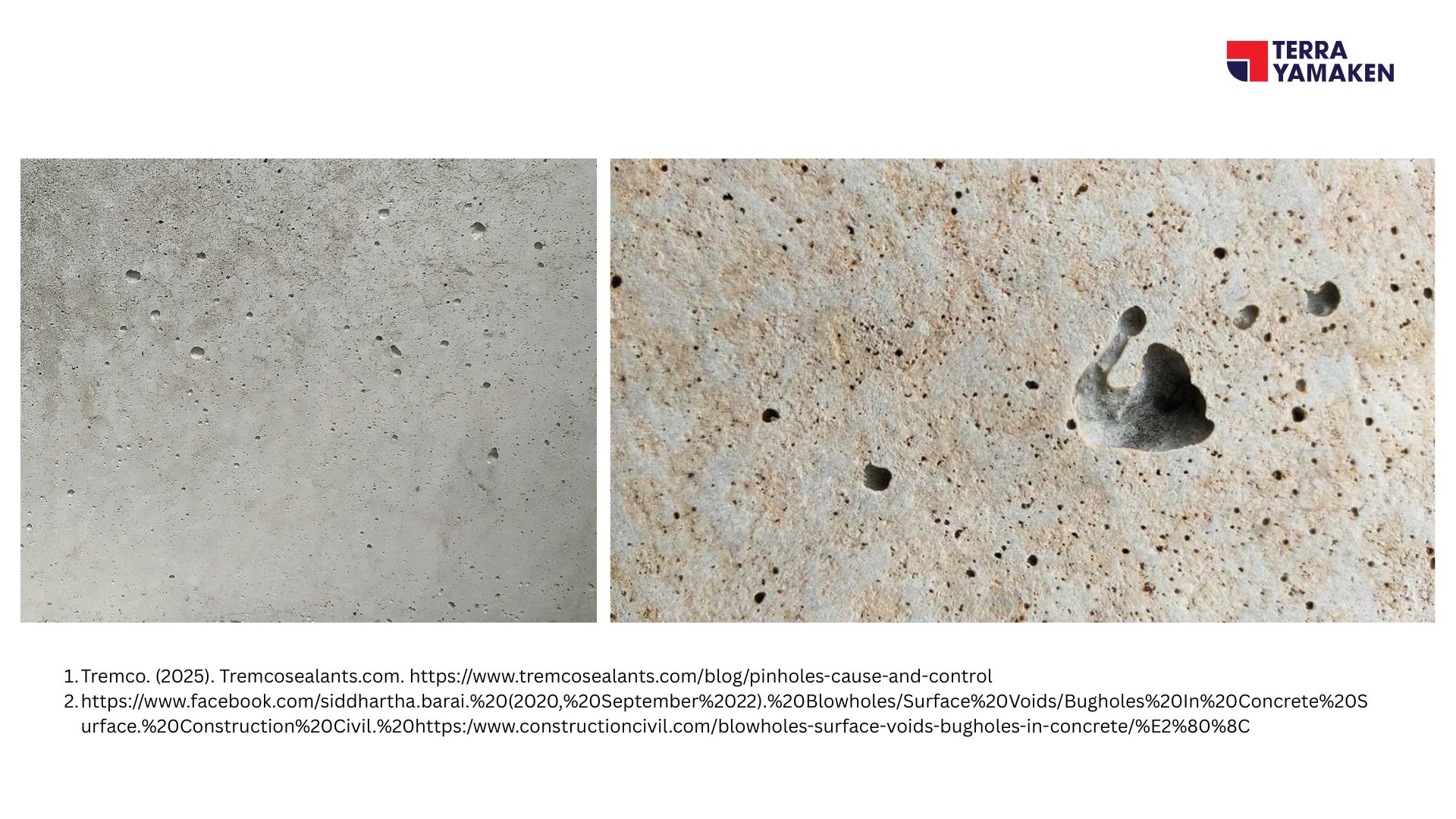

Bugholes, also referred to as surface voids, are small cavities with regular or irregular shapes, typically not exceeding 16 mm in diameter. These voids form due to the entrapment of air bubbles on the surface of cast-in-place concrete during placement and vibration. Bugholes commonly appear on vertical surfaces of in-situ concrete elements. Although they are considered a natural occurrence in vertically cast concrete components, the allowable size or quantity of bugholes is not specified for smooth-finished surfaces in ACI 301-99. However, ACI 301-10 provides guidance on patching procedures based on different surface finish classes. Bugholes are generally not classified as defects unless otherwise specified in the project contract documents.

Figure 2 – Bugholes on Concrete Surface

The occurrence of bugholes is influenced by several factors, including the texture and adhesion of the formwork surface, surface inclination, concrete mix design, and vibration technique. To minimize bughole formation, it is recommended to use rigid, well-braced formwork, avoid inward-sloping surfaces, apply a thin layer of non-stick release agent, utilize absorptive formwork when appropriate, avoid overly sticky concrete mixes, and ensure thorough consolidation during placement. Controlling bugholes not only enhances the visual appearance but also contributes to the durability and overall quality of the concrete structure.

Distinction Between Air Content and Bugholes in Concrete

The difference between air content and bugholes lies in their nature and impact on concrete performance:

1. Air Content in Fresh Concrete

– Definition: The volume of air entrained—either intentionally or unintentionally—into the concrete mix during batching. These air voids are uniformly distributed throughout the mix.

– Purpose: Air entrainment improves workability and enhances freeze-thaw resistance. It is a controlled process that helps mitigate cracking due to thermal cycling.

– Measurement: Air content is determined using standardized test methods such as TCVN 3111:2022 or equivalent international standards.

2. Bugholes (Surface Voids)

– Definition: Unwanted, irregular voids formed on the concrete surface adjacent to formwork, becoming visible after form removal.

– Cause: Caused by trapped air at the formwork interface during placement. Factors such as formwork texture, concrete mix properties, and vibration technique influence their formation.

– Impact: Typically considered an aesthetic issue, but excessive or large bugholes may compromise surface durability.

Conclusion

In summary, entrained air in fresh concrete is a controlled characteristic that offers structural benefits, such as improved workability and resistance to freeze-thaw cycles. For conventional heavy concrete, a small amount of air—typically less than 2%—may be entrained during mixing. In contrast, bugholes are surface imperfections caused by trapped air during placement and consolidation. While often cosmetic, a high concentration of bugholes can reduce surface durability. Minimizing bugholes requires proper formwork design and placement techniques. Effective control of both air content and bugholes is essential for achieving high-quality, durable concrete structures.

Keywords:

- Air content in concrete ratio

- Air content in concrete mix design

- Air content in concrete test

- Air content in concrete slab

- Air content in concrete formula

- Air content in concrete table

- Why is air content in concrete important

- Air content test for concrete pdf

Sources:

[1] Air Content Testing Apparatus Used to Measure Entrained Air in Concrete

[2] Tremco. (2025). Tremcosealants.com. https://www.tremcosealants.com/blog/pinholes-cause-and-control

[3] https://www.facebook.com/siddhartha.barai. (2020, September 22). Blowholes/Surface Voids/Bugholes In Concrete Surface. Construction Civil. https://www.constructioncivil.com/blowholes-surface-voids-bugholes-in-concrete/

[4] Standard Test Method for Air Content of Freshly Mixed Concrete by the Pressure Method