Table of Contents

ToggleCrushed sand, also referred to as manufactured sand (M-sand), is specified in standards such as ASTM C33 and TCVN 9205:2012. It is a type of fine aggregate produced by mechanically crushing rock to achieve the required particle size distribution. It is accepted as an alternative to natural sand in concrete production when it complies with the requirements of these standards.

According to these specifications, fine aggregates for concrete may include natural sand, manufactured sand, or a blend of both. The standards emphasize that manufactured sand must be clean, hard, and free from deleterious substances. The shift toward using crushed sand is driven by:

- Scarcity of natural sand resources: River sand reserves are depleting, and extraction is increasingly restricted due to environmental protection requirements.

- Sustainability demands: Manufactured sand helps conserve natural resources and reduce ecological impact.

Key Advantages:

- Better control over particle size distribution, enabling optimized concrete mix design.

- Improved particle packing, reducing voids and enhancing compressive strength.

- More consistent quality compared to natural sand, which varies by source.

Standards such as ASTM C33 and TCVN 9205:2012 provide the technical basis to ensure that crushed sand delivers performance equivalent to or superior to natural sand in terms of workability, strength development, and long-term durability.

Environmental and Economic Drivers for Using Crushed Sand

International and national standards—such as ASTM C33 and TCVN 9205:2012—recognize natural sand as the traditional fine aggregate for concrete and mortar, while permitting manufactured sand (M-sand) as a viable alternative. This trend stems from increasing restrictions on river sand extraction due to environmental protection requirements and the depletion of natural resources.

Crushed sand not only conserves natural resources but also utilizes quarried rock or mining by-products, reducing transportation costs and ensuring a stable supply chain. When meeting technical requirements for fineness modulus, particle grading, cleanliness, and chemical-physical properties as specified in TCVN 9205:2012, manufactured sand offers superior quality control, optimized mix design, and improved concrete uniformity.

Standards and Industry Practice

- Vietnam: TCVN 9205:2012 clearly defines scope, technical requirements, and test methods for crushed stone sand used in concrete and mortar. It specifies limits for fineness modulus, particle size distribution, fine content, clay content, chloride ions, and alkali–silica reactivity to ensure durability and concrete quality. Compliance with these requirements makes crushed sand a practical substitute for natural sand, aligning with environmental protection and material supply stability.

- International: ASTM C33 establishes general principles for using manufactured fine aggregates, emphasizing control of deleterious substances and long-term durability.

Both standards aim to ensure that crushed sand delivers performance equivalent to or better than natural sand in terms of workability, strength development, and durability.

Objectives and Benefits of Using Crushed Sand

- Natural Sand Replacement: Addresses depletion of river sand resources and mitigates environmental impacts from over-extraction.

- Sustainability and Cost Efficiency: Utilizes quarried rock or mining waste, reduces haulage costs, and supports sustainable construction practices.

- Performance Improvement: When meeting technical specifications for grading and cleanliness, crushed sand enhances particle packing, reduces voids, improves compressive strength, and ensures consistent mix uniformity.

Role in Improving Concrete Properties

- Workability: Properly graded crushed sand, controlled for fineness modulus and fine particle limits (<75 µm and <140 µm), maintains mix uniformity, minimizes bleeding, and ensures pumpability.

- Strength: Compliance with limits on clay content (≤2%) and control of alkali–silica reactivity promotes better particle interlock and higher packing density, resulting in improved compressive strength and long-term durability for concrete and mortar.

Standards and Related Regulations

- TCVN 9205:2012 – Crushed Sand for Concrete and Mortar:

Specifies scope of application, technical requirements, and test methods for crushed sand produced from natural rock. - ASTM C33-08 & ASTM C33-18 – Standard Specification for Concrete Aggregates:

Defines grading and quality requirements for fine and coarse aggregates, including manufactured sand, with provisions on deleterious substances, soundness, and alkali–aggregate reactivity.

Key Technical Requirements

Particle Size Distribution (Grading)

ASTM C33:

- Fine aggregate must comply with sieve analysis limits (e.g., 95–100% passing No.4 sieve; 0–3% passing No.200 sieve for natural sand; up to 5–7% for manufactured sand if crusher fines are clean and free from clay/shale).

- Fineness modulus: 2.3–3.1.

TCVN 9205:2012:

- Coarse sand: Fineness modulus > 2.0 to 3.3.

- Fine sand: Fineness modulus from 0.7 to 2.0.

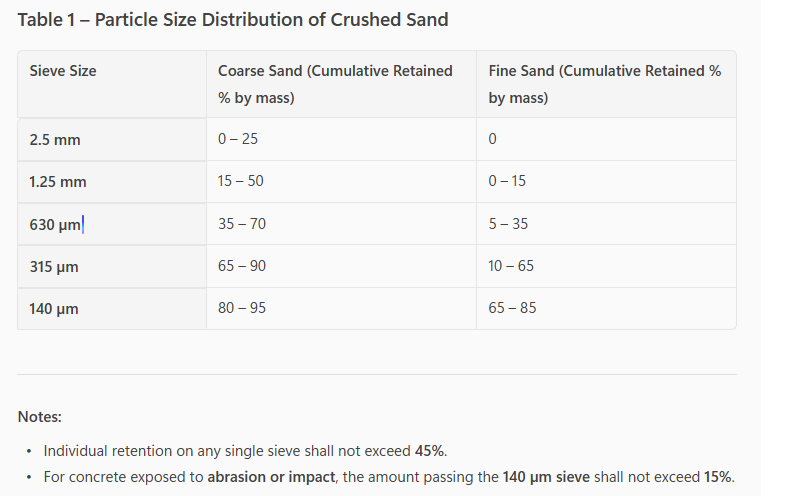

- Particle size distribution must fall within specified limits in Table 1:

- For coarse sand, cumulative retained on 315 µm sieve: 65–90%.

- For fine sand, cumulative retained on 315 µm sieve: 10–65%.

Note: Individual sieve retention shall not exceed 45%, and for concrete exposed to abrasion or impact, the amount passing the 140 µm sieve shall not exceed 15%.

Figure 1 – Particle Size Distribution (Grading) Extracted from TCVN 9205:2012, Section 3.2 – Grading of Crushed Sand, expressed as cumulative retained on sieves within specified limits.

Cleanliness

Aggregates for concrete and mortar must be free from organic impurities, clay lumps, and any substances detrimental to concrete quality.

According to ASTM C33:

- Organic impurities tested per ASTM C40.

- Clay lumps and friable particles: ≤ 3% by mass.

- Coal and lignite: ≤ 1% (reduced to 0.5% for architectural concrete requiring high surface finish).

According to TCVN 9205:2012:

- Clay content: ≤ 2%.

- Acid-soluble chloride ions: ≤ 0.05% for conventional reinforced concrete and ≤ 0.01% for prestressed concrete (see Table 2).

- Crushed sand must be tested for alkali–silica reactivity to ensure it falls within the non-reactive aggregate category.

Particle Shape

Both standards require aggregates to have high hardness and durability, free from flat or elongated particles that could impair mix uniformity and structural performance.

- ASTM C33: Aggregates must have stable particle shape, avoiding excessive flaky or elongated particles to ensure proper compaction and minimize segregation in concrete mixes.

- TCVN 9205:2012: For crushed sand, grading must comply with fineness modulus and fine particle limits to ensure good packing. For coarse aggregates (refer to TCVN 7570:2006), limits on flakiness and elongation indices are specified to maintain shape stability and mechanical strength.

Fines Content

Controlling fines is critical for maintaining workability and durability of concrete.

According to ASTM C33:

- Material passing 75 µm (No.200 sieve): ≤ 3% for natural sand.

- For manufactured sand, if fines are clean crusher dust free from clay or harmful impurities, the limit may increase to 5% for abrasion-resistant concrete and 7% for general concrete.

According to TCVN 9205:2012:

- Material passing 75 µm sieve: ≤ 16% for coarse sand, ≤ 25% for fine sand.

- For concrete exposed to abrasion or impact: ≤ 9%.

- Additionally, material passing 140 µm sieve is strictly controlled to ensure cleanliness and grading stability.

Technical Benefits

Standards such as ASTM C33 and TCVN 9205:2012 permit the use of manufactured sand (crushed sand) when requirements for particle grading, fineness modulus, and cleanliness are met. This provides significant advantages for concrete quality and performance:

Optimized Particle Interlock and Concrete Density

Manufactured sand has angular particle shape, which promotes better interlocking within the concrete matrix. Improved packing reduces voids, enhances load transfer, and increases compressive strength, making it ideal for structural concrete requiring high durability.

Controlled Grading and Mix Design

The production process allows adjustment of particle size distribution to meet standard specifications, ensuring consistency and reducing variability compared to natural sand. This supports optimized mix design, improves workability, and minimizes bleeding. Controlled fines content within specified limits reduces the risk of plastic shrinkage and improves mix stability.

Economic Efficiency and Sustainability

Manufactured sand can be produced from local quarried rock or mine waste, reducing transportation costs and dependence on increasingly scarce river sand. Its use conserves natural resources, limits riverbed mining, mitigates ecological impact, and supports sustainable construction practices.

Typical Applications

Structural Concrete

Standards such as ASTM C33 and TCVN 9205:2012 allow manufactured sand as fine aggregate for concrete, including structural applications, provided grading, fineness modulus, and cleanliness requirements are met. This enables substitution for natural sand in load-bearing elements, where long-term strength and stability are critical.

For reinforced concrete, controlling harmful impurities is essential to prevent steel corrosion and ensure service life.

- TCVN 9205:2012: Acid-soluble chloride ions ≤ 0.05% for conventional reinforced concrete and ≤ 0.01% for prestressed concrete (Table 2). Clay content ≤ 2%, and alkali–silica reactivity testing is required to confirm non-reactive aggregates.

- ASTM C33: Limits on organic impurities, clay lumps, coal, and lignite, with mandatory testing to verify concrete durability and stability.

These requirements maintain structural integrity and ensure long-term durability in real-world applications.

High-Performance Concrete (HPC)

In HPC production, stringent demands for strength, durability, and resistance to aggressive environments apply. TCVN 9205:2012 permits manufactured sand when meeting specifications for fineness modulus, grading, cleanliness, and impurity limits. The angular shape of crushed sand enhances particle interlock and matrix density, reducing voids and improving load transfer, thereby increasing compressive strength and long-term durability.

To ensure stability in aggressive environments, standards require:

- Fines passing 75 µm sieve: ≤ 16% for coarse sand, ≤ 25% for fine sand, and ≤ 9% for abrasion-resistant concrete.

- Chloride ion content: ≤ 0.05% for conventional reinforced concrete and ≤ 0.01% for prestressed concrete.

- Alkali–silica reactivity testing to confirm aggregate safety.

Figure 2 – Chloride Ion Content in Manufactured Sand, extracted from TCVN 9205:2012, Table 2.

ASTM C33 Requirements and Emphasis

ASTM C33 also highlights the need for soundness testing and alkali–aggregate reactivity assessment, while specifying limits for material passing the 75 µm (No.200) sieve:

- ≤ 3% for natural sand

- ≤ 5–7% for manufactured sand, provided crusher fines are clean and free from clay or deleterious materials.

When these requirements are met and combined with high-range water-reducing admixtures (superplasticizers) and an optimized mix design, manufactured sand becomes an ideal choice for high-performance concrete (HPC), satisfying both technical and sustainability criteria.

Precast Concrete Elements

In precast concrete production, dimensional accuracy and surface finish quality are critical, requiring fine aggregates with stable particle size distribution and appropriate fineness modulus.

- ASTM C33: Specifies fineness modulus for fine aggregate in the range of 2.3–3.1, along with strict grading limits per sieve analysis tables.

- TCVN 9205:2012: Classifies crushed sand into:

- Coarse sand: Fineness modulus > 2.0 to 3.3

- Fine sand: Fineness modulus 0.7 to 2.0

Particle size distribution must comply with Table 1 limits to ensure proper packing and mix uniformity. Manufactured sand produced under controlled grading can consistently meet these limits, reducing variability compared to natural sand. This enhances workability, ensures dense packing, and delivers smooth surface finishes for precast products, improving both uniformity and aesthetic quality.

Suitable Applications and Exposure Conditions

TCVN 9205:2012 permits crushed sand for concrete and mortar when requirements for grading, fineness modulus, and cleanliness are met. With controlled mix design and improved particle packing, manufactured sand is suitable for various structures, especially high-load applications such as bridges, pavements, and high-rise buildings, improving durability and reducing voids in concrete.

For aggressive environments or coastal areas, standards require strict control of chemical and physical properties to ensure long-term durability:

- Acid-soluble chloride ions:

- ≤ 0.05% for conventional reinforced concrete

- ≤ 0.01% for prestressed concrete (Table 2)

- Alkali–silica reactivity testing to confirm non-reactive aggregates, preventing cracking and strength loss.

- Clay content: ≤ 2%, with fines controlled within specified limits to maintain mix stability.

These requirements make manufactured sand a sustainable solution, particularly in regions with limited natural sand resources, reducing riverbed mining and supporting environmental protection.

Figure 2 – Chloride Ion Content in Manufactured Sand, extracted from TCVN 9205:2012, Table 2.

Challenges and Solutions

Using manufactured sand in concrete offers many benefits but also introduces technical requirements that must be carefully controlled:

Workability

Due to its angular particle shape and higher fines content, manufactured sand often increases water demand, reduces slump, and can cause pumping difficulties if the mix design is not optimized. ASTM C33 notes that grading near the lower limits for the 300 µm and 150 µm sieves may lead to bleeding and reduced mix stability.

Water Demand and Mix Proportioning

Excess fines beyond permissible limits increase the water–cement ratio, negatively impacting strength and long-term durability.

TCVN 9205:2012 specifies that particles smaller than 75 µm must not exceed 16% for coarse sand and 25% for fine sand, with clay content limited to ≤ 2%.

Recommended Solutions

- Use high-range water-reducing admixtures (superplasticizers) to lower water demand while maintaining workability, combined with mineral admixtures or air-entraining agents to improve pumpability.

- Optimize mix design by adjusting fineness modulus, blending manufactured sand with natural sand or other aggregates to achieve proper grading.

- Control fines quality, ensuring crusher dust is clean and free from clay minerals, and perform tests for organic impurities and alkali–silica reactivity to prevent durability issues.

These measures ensure manufactured sand meets technical requirements, maintaining concrete performance and durability in practical applications.

Future Outlook for Manufactured Sand in Sustainable Construction

The depletion of natural sand resources and increasingly strict environmental regulations are driving the adoption of manufactured sand in the construction industry. Technical standards such as ASTM C33 and TCVN 9205:2012 provide a clear legal and technical framework, ensuring safe and reliable use of manufactured sand in structural concrete, high-performance concrete, and precast products.

When combined with optimized mix design and advanced admixture technology, manufactured sand not only improves workability but also enhances long-term durability. With these advantages, manufactured sand is expected to become a key material in green construction practices, contributing to resource conservation and reducing environmental impact.

Ralated posts:

- Impact of Rain on Concrete and Quality Assurance During the Rainy Season

- The Difference Between Air Content and Bugholes in Concrete?

Keywords:

- river sand

- density of crushed sand in kg m3

- density of crushed sand

- 7 days to die crushed sand

- silt content in crushed sand as per is code

- specific gravity of crushed sand

- difference between m sand and crushed sand

- 7 days to die sand vs crushed sand

- fineness modulus of crushed sand

- washed sand vs crushed sand

Sources: