Table of Contents

ToggleIn the context of the construction industry moving toward sustainable development and reducing CO₂ emissions, finding alternatives to Portland cement has become imperative. Ground Granulated Blast Furnace Slag (GGBFS) emerges as an effective solution, leveraging industrial by-products while enhancing concrete quality. With its latent hydraulic properties, GGBFS not only reduces clinker production but also improves long-term durability, resistance to aggressive environments, and mitigates early-age cracking. This represents a key trend in circular economy and green concrete technology.

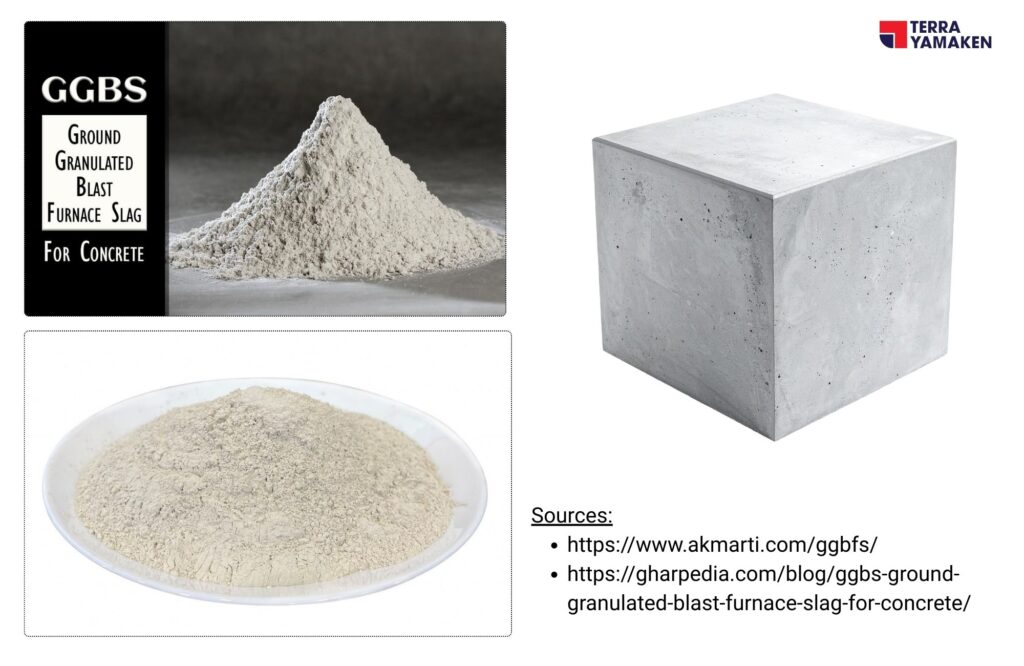

Introduction to Ground Granulated Blast Furnace Slag (GGBFS)

Origin

Ground Granulated Blast Furnace Slag is a by-product generated during the iron-making process in a blast furnace. When molten slag is rapidly quenched with water, it forms a granular material with a glassy structure. This material exhibits latent hydraulic properties, meaning it can react when combined with Portland cement in an alkaline environment.

Production Process

The granulated slag is finely ground to the required fineness for use as a reactive mineral admixture in concrete and mortar. In some cases, a small amount of gypsum and processing additives (not exceeding 1%) may be added to ensure concrete quality and reinforcement protection are not compromised. According to TCVN 11586:2016 – Ground Granulated Blast Furnace Slag for Concrete and Mortar, the product must meet technical requirements for fineness, strength activity index, chemical composition, and moisture content.

Role of GGBFS in Sustainability and CO₂ Emission Reduction

By partially replacing Portland cement in concrete mixes, GGBFS significantly reduces CO₂ emissions associated with clinker production—one of the largest sources of greenhouse gas emissions in the construction industry. Additionally, it utilizes industrial by-products from the steelmaking process, contributing to the circular economy and reducing waste disposal pressure.

Enhancing Long-Term Durability of Concrete

Beyond environmental benefits, GGBFS improves the mechanical and durability properties of concrete:

- Increases resistance to sulfate and chloride attack, reducing reinforcement corrosion.

- Lowers heat of hydration, minimizing early-age cracking in mass concrete.

- Improves workability of mortar, facilitating easier placement and finishing.

- Enhances long-term strength, ensuring more durable structures.

Technical Standards

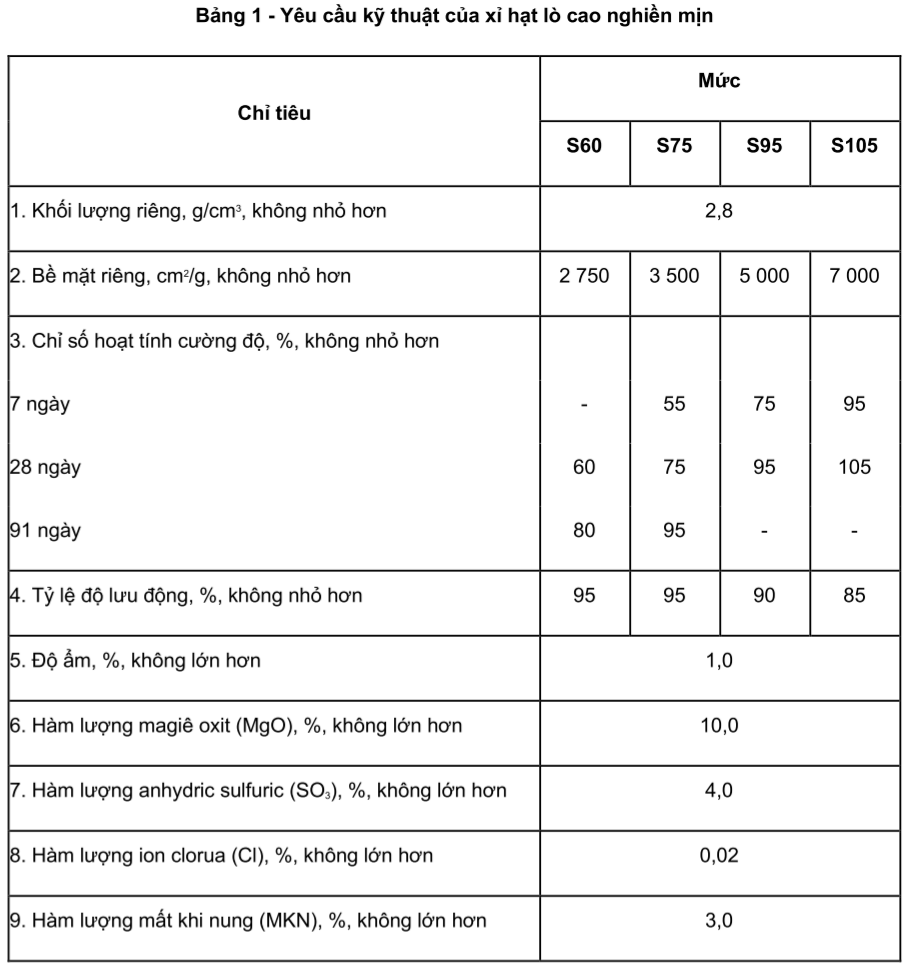

According to TCVN 11586:2016, GGBFS used in concrete and mortar must comply with the technical requirements specified in Table 1.

Figure 1: TCVN 11586:2016 (Table 1) – Technical Requirements for Ground Granulated Blast Furnace Slag (GGBFS)

Ground Granulated Blast Furnace Slag is classified into four grades based on the strength activity index at 28 days: S60, S75, S95, and S105. This classification enables engineers to select the appropriate GGBFS type according to design requirements and construction conditions. The technical criteria are specified to ensure that GGBFS does not adversely affect concrete quality or reinforcement protection. These limits include: specific gravity, fineness (specific surface area), strength activity index, moisture content, MgO, SO₃, chloride ion (Cl⁻), and loss on ignition (LOI).

Benefits of Using GGBFS in Concrete and Mortar

Technical Benefits

- Quality and Stability: Limits on fineness (≤ 20% retained on 45 µm sieve) and specific surface area requirements help control hydraulic reactivity, ensuring concrete meets design strength (Table 1 – Physical Requirements). [1]

- Improved Long-Term Strength: Classification by Grade 80, 100, 120 based on 28-day activity index (≥ 75%, 95%, 115%) allows selection for higher strength performance (Section 4.1 & Table 1). [1]

- Reduced Expansion Risk: CaSO₄ additive limits and expansion test (≤ 0.020% after 14 days) minimize cracking due to chemical reactions (Section 6.1.1). [1]

Durability and Resistance

- Superior Sulfate Resistance: High slag replacement (≥ 60%) significantly improves sulfate attack resistance compared to ordinary Portland cement (Appendix X2 – Sulfate Resistance). [1]

- Mitigation of Alkali-Silica Reaction (ASR): Slag reduces total alkalis and consumes alkalis during hydration, limiting ASR-induced cracking (Appendix X3 – Effectiveness in Preventing ASR). [1]

Environmental and Economic Benefits

- Lower CO₂ Emissions: Partial replacement of Portland cement reduces clinker production, cutting greenhouse gas emissions (Scope 1.1 – Use for Blending with Portland Cement). [1]

- Industrial By-Product Utilization: Reuse of blast furnace slag supports circular economy and waste reduction (General Context of Specification). [1]

- Cost Savings: Reduced Portland cement content lowers material costs, especially for mass concrete applications (Appendix X1 – Contribution to Concrete Strength). [1]

Construction Advantages

- Improved Workability: Slag enhances mortar flowability, facilitating placement and finishing (Section 10.1.3 – Mortar Preparation). [1]

- Lower Heat of Hydration: Reduces early-age cracking in mass concrete, ideal for dams, deep foundations, and large structural elements (Appendix X1 – Strength Development and Heat of Hydration). [1]

Performance Under High Temperature

- Reduced Mass Loss: Concrete with GGBFS loses only 1.5–5% mass when heated to 350 °C, lower than conventional concrete. [4]

Higher Residual Compressive Strength: After heating to 350 °C, compressive strength increases by 15.6% with 20% GGBFS, while conventional concrete declines sharply. [4]

Less Strength Degradation Over Time: At 56 days, compressive strength reduction is less severe in GGBFS mixes compared to control samples. [4]

Better Tensile Strength and Elastic Modulus Retention: GGBFS mixes exhibit less deterioration, maintaining mechanical properties under high-temperature conditions. [4]

Sources:

[1] Kim, Y.-J., Kim, S.-C., & Kim, Y.-T. (2003). Corrosion resistance and hydration heat of concrete containing ground granulated blast furnace slag. KSCE Journal of Civil Engineering, 7(4), 399–404.

[2] Huang, X., Liao, J., Zhang, J., Wang, Y., & Feng, Q. (2025). Insight into the durability of concrete based on ultrafine ground granulated blast furnace slag, phosphogypsum, and steel slag. Journal of Materials Research and Technology, 38, 49–61. https://doi.org/10.1016/j.jmrt.2025.07.206

[3] Zhou, P., Gu, K., & Jiang, Z. (2024). Preparation and properties of non-autoclaved high-strength pile concrete with anhydrite and ground granulated blast-furnace slag. Case Studies in Construction Materials, 21, e03597. https://doi.org/10.1016/j.cscm.2024.e03597

[4] Siddique, R., & Kaur, D. (2011). Properties of concrete containing ground granulated blast furnace slag (GGBFS) at elevated temperatures. Journal of Advanced Research, 3(1), 45–51. https://doi.org/10.1016/j.jare.2011.03.004

[5] Vietnam Standardization Agency. (2016). TCVN 11586:2016 – Xỉ hạt lò cao nghiền mịn dùng cho bê tông và vữa [Ground granulated blast-furnace slag for concrete and mortar]. Hanoi: Ministry of Science and Technology.

Ralated posts

- Using Fly Ash as a Pozzolanic Mineral Admixture in Concrete: Context, Purpose, Permissible Standards, and Benefits

- Crushed sand (artificial sand) for concrete production | Key Technical Requirements

- Impact of Rain on Concrete and Quality Assurance During the Rainy Season

Keywords

- Ground granulated blast furnace slag price

- Ground granulated blast furnace slag production

- Ground Granulated blast furnace slag supplier

- Ground granulated blast furnace slag hs code

- Ground granulated blast furnace slag chemical composition

- Ground granulated blast furnace slag ratio

- Ground granulated blast furnace slag near me

- Ground Granulated Blast Furnace Slag buy