Table of Contents

ToggleFrom the professional standpoint of a construction engineer, the Vietnamese standard TCVN 9341:2012 – Mass Concrete: Construction and Acceptance [1] serves as a core technical guideline, providing a comprehensive framework for ensuring the quality, durability, and structural stability of large-scale concrete elements. Proper implementation of this standard is essential not only for mitigating technical risks such as thermal cracking caused by cement hydration heat, but also for improving construction efficiency and extending the service life of the structure.

This document outlines practical approaches for engineers, contractors, and consultants to apply the standard effectively on-site, ensuring safe, scientific, and high-performance execution of mass concrete works.

Definition of Mass Concrete

Mass concrete refers to concrete or reinforced concrete structures with dimensions large enough to generate significant tensile stresses due to the heat of hydration during curing. When these internal stresses exceed the tensile strength of the concrete, thermal cracking can occur. According to TCVN 9341:2012, in Vietnam’s hot and humid climate, any structural element with a minimum dimension or height greater than 2 meters is classified as mass concrete. For complex geometries such as interlocking joints or irregular blocks, the determination of mass concrete classification is left to the discretion of the structural designer.

Would you like me to continue with the technical breakdown of placement procedures, temperature control, or curing methods as outlined in the standard?

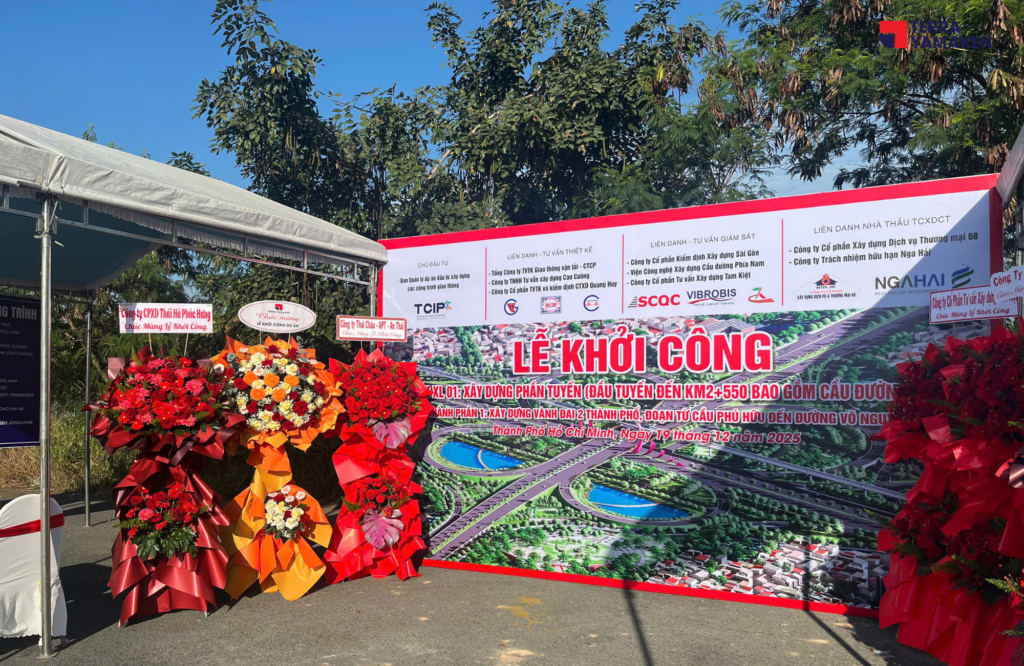

Figure 1 – Mass Concrete Placement at Dam Sites (Source: EngineeringCivil.org) [2]

This image illustrates the construction process of mass concrete in large-scale hydraulic structures such as dams. It highlights key aspects of field execution including layered placement, temperature control measures, and equipment used for continuous pouring. Such visual documentation is essential for understanding the practical challenges and technical solutions involved in managing thermal stresses, hydration heat, and crack prevention in mass concrete applications.

Mass Concrete Construction Requirements

2.1. Concrete Placement by Lift (Pour Sequence)

- The maximum height of each lift (or pour sequence) must not exceed 1.5 meters.

- The minimum interval between successive lifts should be no less than 4 full days and nights after the completion of the previous lift.

Technical Rationale:

- Limiting lift height helps control the temperature rise caused by the exothermic hydration reaction of cement, thereby minimizing thermal gradients that can lead to cracking.

- Ensures effective compaction and homogeneity of the concrete mass.

- Facilitates better construction scheduling and quality control.

- Maintains structural integrity throughout the placement process.

2.2. Concrete Placement by Layer (Layered Pouring)

- The maximum thickness of each layer should not exceed 50 centimeters.

- Layers must be placed and compacted continuously in cycles until the full lift height is achieved.

- The maximum cycle time for each layer is 1 hour in summer and 2 hours in winter, depending on ambient conditions.

Technical Rationale:

- Promotes efficient vibration and consolidation, preventing segregation and enhancing density.

- Helps regulate internal temperature during placement, especially under hot weather conditions.

- Maintains continuity and uniformity of the concrete structure.

- Adapts to seasonal variations to ensure consistent quality.

2.3. Nighttime Concrete Placement

- During hot summer conditions, placing concrete at night is a recommended method to reduce the rate of heat generation from cement hydration.

- This practice significantly lowers the risk of thermal cracking, especially in massive pours where heat dissipation is limited.

Technical Measures for Preventing Thermal Cracking in Mass Concrete

(Based on TCVN 9341:2012 – Section 3)

To effectively manage thermal effects during the setting and hardening of mass concrete, the Vietnamese standard TCVN 9341:2012 outlines a series of technical strategies aimed at minimizing the risk of thermal cracking caused by the heat of cement hydration. These measures are critical for maintaining structural integrity, especially in large-volume pours where heat dissipation is limited.

3.1. Limiting the Rate of Heat Generation from Cement Hydration

Reducing Cement Content in the Mix: One of the most effective methods to control hydration heat is to minimize the cement dosage in the concrete mix. This can be achieved through:

- Low-slump mix design: Designing concrete with the lowest possible slump reduces water demand, which in turn lowers the required cement content while still achieving the desired workability and strength.

- Use of water-reducing admixtures: These admixtures maintain workability while allowing for a reduction in both water and cement content, thereby decreasing the heat generated during hydration.

- Roller-compacted concrete (RCC): RCC is a dry mix with low cement content, compacted using vibratory rollers. It is ideal for mass concrete applications due to its low heat generation and high placement efficiency.

Using Low-Heat Cement Types: The choice of cement plays a vital role in controlling thermal behavior:

- Ordinary Portland Cement (OPC): Should have a hydration heat not exceeding 293.02 J/g after 7 days. Suitable for general applications without stringent thermal control requirements.

- Low-heat Portland Cement: Recommended for critical structures such as dams, deep foundations, and large water-retaining structures, with hydration heat limited to 251.16 J/g after 7 days.

- Portland-Pozzolan or Portland-Slag Cement: These types offer enhanced sulfate resistance and durability, making them suitable for coastal or acidic environments. They also contribute to lower heat evolution and improved long-term performance.

Controlling Initial Concrete Temperature: As per Clause 6.7.1.3 of TCVN 9341:2012, the fresh concrete temperature prior to placement should be kept below 25°C, ideally under 20°C. To achieve this:

- Cool aggregate and mixing water: Store aggregates under shade, use chilled water or ice, or apply liquid nitrogen to reduce mix temperature.

- Protect mixed concrete before placement: Use insulated covers or shaded areas to prevent heat gain from ambient conditions.

3.2. Minimizing Temperature Differential (ΔT) Within the Concrete Mass

To prevent internal thermal gradients that lead to cracking:

- Install embedded cooling pipes: These allow controlled heat extraction from the concrete core.

- Apply thermal insulation: Cover the surface with insulating materials to retain heat and balance the temperature between the core and surface.

- Segment the pour: Divide the mass into smaller blocks to facilitate heat dissipation and improve construction control.

- Careful formwork removal: Avoid thermal shock by removing formwork gradually and under controlled conditions.

These technical measures, when properly implemented, form a comprehensive strategy for thermal stress management in mass concrete construction. Adhering to TCVN 9341:2012 not only ensures compliance but also enhances the durability, safety, and performance of large-scale concrete structures.

Mass Concrete Curing Procedures

Curing is a critical phase in mass concrete construction, essential for achieving the desired strength, durability, and long-term performance of the structure. Proper curing helps regulate internal temperature, control moisture loss, and prevent thermal cracking caused by hydration heat. According to TCVN 9341:2012, the following methods are recommended:

Water Curing

- Continuous water spraying or ponding on the concrete surface is used to maintain surface moisture and facilitate heat dissipation.

- The temperature of the curing water should not differ by more than 15°C from the concrete surface to avoid thermal shock, which can lead to surface cracking.

Insulated Curing

- Immediately after placement, the concrete surface should be covered with thermal insulation materials such as expanded polystyrene sheets or organic insulating layers like rice husks.

- This method helps retain internal heat, promoting uniform temperature distribution between the core and surface, thereby reducing the risk of temperature gradient-induced cracking.

Sunlight Protection

- During hot weather conditions, especially in summer, the concrete mass must be shielded from direct sunlight for at least two weeks post-placement.

- This measure prevents excessive heat gain on the surface, which could exacerbate internal temperature differentials and increase the likelihood of cracking.

Conclusion

Mass concrete construction is a technically demanding process that requires strict adherence to engineering standards to ensure structural integrity. Effective temperature control, appropriate material selection, layered placement techniques, and proper curing practices are all vital to preventing thermal cracking—one of the most critical risks in large-volume concrete pours. By following the guidelines outlined in TCVN 9341:2012, engineers and contractors can significantly enhance the quality, safety, and service life of mass concrete structures.

Related post

- Risk Assessment and Technical Solutions for Common Types of Concrete Cracks

- Effective Concrete Curing in Vietnam’s Climate

- Understanding Plastic Shrinkage Cracking in Concrete: Causes and Mitigation Strategies

Keywords

- Mass concreting meaning

- Mass concrete examples

- Mass concrete ratio

- Mass concrete vs reinforced concrete

- Mass concrete specification

- Mass concrete dimensions

- Mass concrete thickness

- Mass concrete grade

References:

- [1] Nam. (2025). Tiêu chuẩn: TCVN 9341:2012 – Bê tông khối lớn – Thi công và nghiệm thu. Vsqi.gov.vn. https://tieuchuan.vsqi.gov.vn/tieuchuan/view?sohieu=TCVN+9341%3A2012

- [2] CivilEngineeringTutor. (2023, January 11). Managing Mass Concrete Pours at Dams. EngineeringCivil.org. https://engineeringcivil.org/articles/managing-mass-concrete-pours-at-dams/