Products – Services – Solutions

PRODUCTS &

SERVICES

PRODUCTS & SERVICES

CONCRETE PRODUCTS MEETING STANDARD REQUIREMENTS

- TCVN 9340:2012 _ Ready-mixed concrete - Basic quality assessment and acceptance requirements

- BSEN 206-1 _ Concrete - Part 1: Specification, performance, production and conformity.

- ASTM C94/C 94M – Standard Specification for Ready-Mixed Concrete

PRODUCTS BY COMPRESSIVE STRENGTH GRADE

- TCVN 9340:2012 _ Hỗn hợp bê tông trộn sẵn - Yêu cầu cơ bản đánh giá chất lượng và nghiệm thu

- BSEN 206-1 _ Concrete - Part 1: Specification, performance, production and conformity.

- ASTM C94/C 94M – Standard Specification for Ready-Mixed Concrete

PRODUCTS BY CONCRETE MIX DESIGN (GRADE)

- TCVN 9340:2012 _ Hỗn hợp bê tông trộn sẵn - Yêu cầu cơ bản đánh giá chất lượng và nghiệm thu

- BSEN 206-1 _ Concrete - Part 1: Specification, performance, production and conformity.

- ASTM C94/C 94M – Standard Specification for Ready-Mixed Concrete

INDUSTRIAL FACTORY SOLUTIONS

INDUSTRIAL FACTORY

SOLUTIONS

LOW-SHRINKAGE CONCRETE

Characteristics:

Low-shrinkage concrete is engineered with properties suitable for applications requiring high dimensional stability, minimizing cracking and shrinkage phenomena. This material exhibits excellent moisture retention, contributing to enhanced durability and extended service life of the structure.

Applications:

- Large-scale industrial flooring

- High-strength structural concrete elements

- Projects requiring high-quality surface finishes

- Constructions demanding minimized concrete shrinkage and expansion

Benefits:

- Minimizes cracking due to shrinkage and thermal variation

- Enhances tensile strength and impact resistance

- Provides durable, aesthetically pleasing, and low-maintenance concrete surfaces

HIGH-DURABILITY CONCRETE

Characteristics:

High-durability concrete is developed to minimize the impact of natural corrosive environments and usage-induced corrosion.

Applications:

High-durability concrete is developed to minimize the impact of natural corrosive environments and usage-induced corrosion.

Benefits:

Ensures long-term durability of structures, reducing maintenance and repair costs.

MASS CONCRETE

Characteristics:

The concrete is specially designed to reduce heat generation from the cement hydration process.

Applications:

Used for large monolithic foundations and large transitional beam systems requiring special construction and curing conditions as per standards.

Benefits:

- Rapid monolithic construction.

- Reduces cracking due to thermal stress from early-stage hydration.

- Compliant with standard requirements.

INDUSTRIAL FLOOR CONCRETE

Characteristics:

Industrial floor concrete is engineered for high load-bearing capacity, abrasion resistance, and superior surface finish. It is suitable for areas requiring mechanical durability and chemical resistance, helping extend service life and reduce maintenance costs.

Applications:

- Manufacturing facilities

- Warehouses and distribution centers

- Supermarkets and commercial malls

- Automotive garages and repair workshops

- Heavy-duty industrial structures

Benefits:

- High resistance to mechanical loads and surface wear

- Complies with stringent industrial performance standards

READY-MIX MORTAR

Characteristics:

Ready-mix mortar is manufactured with precise proportions of sand, cement, and additives according to standards, ensuring consistent and stable quality. This product eliminates the need for on-site mixing, reducing errors and saving construction time.

Applications:

- Brick and stone masonry

- Plastering of walls, floors, and ceilings

- Structural repair and renovation

- Ceramic tile installation

- Projects requiring high-performance mortar

Benefits:

- Saves time and labor by eliminating on-site mixing

- Ensures uniform mortar quality with stable composition

- Easy to use—just add water as instructed

- Minimizes material waste and labor costs

PERVIOUS CONCRETE

Characteristics:

Pervious concrete is engineered to allow water to pass through its surface, minimizing surface runoff and promoting groundwater recharge.

Applications:

- Driveways

- Sidewalks

- Parking lots

- Patios

- Low-traffic roads

Benefits:

- Reduces stormwater runoff.

- Enhances water management in urban areas.

- Supports sustainable development by improving groundwater recharge.

- Mitigates flooding risks.

- Environmentally friendly, promoting green building practices.

FIBER REINFORCED CONCRETE

Characteristics:

Fiber Reinforced Concrete (FRC) is tailored to enhance the mechanical properties of concrete by incorporating fibers, which improve its structural integrity and durability.

Applications:

- Industrial flooring systems

- Bridges, roads, and infrastructure components

- Retaining walls and underground structures

- Architectural elements requiring high durability and aesthetics

Benefits:

- Reduces cracking caused by shrinkage and thermal fluctuations

- Improves tensile and impact resistance

- Provides durable, visually appealing, and low-maintenance surfaces

- Offers design and construction flexibility across various structural forms

COLD STORAGE CONCRETE

Characteristics:

Cold Storage Concrete is specifically designed to withstand low temperatures and prevent moisture penetration, ensuring optimal performance in refrigerated environments.

Applications:

- Cold storage facilities

- Refrigerated warehouses

- Food processing plants

- Ice rinks

- Frozen food distribution centers

Benefits:

- Provides excellent thermal insulation. Minimizes thermal expansion and contraction.

- Prevents moisture ingress and associated damage.

- Maintains structural integrity at low temperatures.

- Ensures energy efficiency and reduced operational costs.

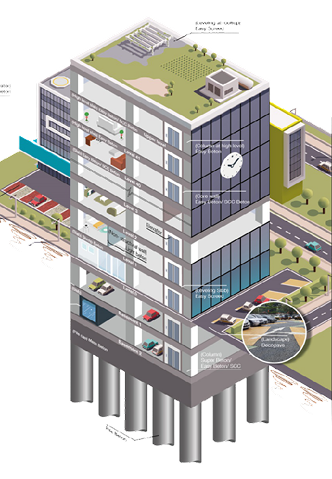

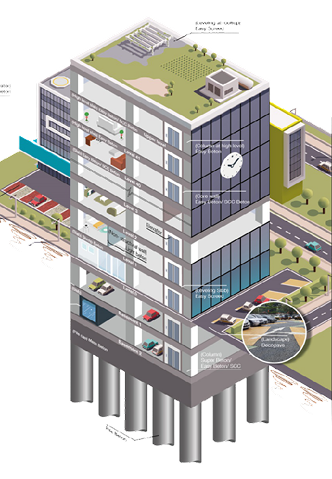

HIGH-RISE BUILDING SOLUTIONS

READY-MIX MORTAR

High-flow ready-mix mortar used for effective finishing projects.

HIGH-WORKABILITY CONCRETE

Used for beams, columns, and walls with dense reinforcement designs that are difficult to compact during construction.

HIGH-STRENGTH CONCRETE

Columns, shear walls, and elevator core walls.

LOW-SHRINKAGE CONCRETE

Suitable for large, exposed surfaces requiring high-quality finishes.

HIGH-DURABILITY CONCRETE

Wastewater treatment tank, aggressive environment

MASS CONCRETE

Foundation, concrete foundation system

BORED PILE CONCRETE - DIAPHRAGM WALL

Deep foundation: Bored pile - Diaphragm wall

READY-MIX MORTAR

Characteristics:

Ready-mix mortar is produced with precise proportions to ensure consistent quality.

Applications:

- Used for leveling foundations

- Floors of high-rise buildings

- Final layer linings

Benefits:

- Quick application

- Saves time and labor

HIGH-WORKABILITY CONCRETE

Characteristics:

High-workability concrete is easy to place in areas with dense reinforcement and hard-to-reach locations.

Applications:

Used for beams, columns, and walls with dense reinforcement designs that are difficult to compact during construction.

Benefits:

- Facilitates faster construction

- Saves time and labor

HIGH-STRENGTH CONCRETE

Characteristics:

This product features a high compressive strength of ≥ 60MPa, making it suitable for structural components requiring heavy load-bearing capacity.

Applications:

Ideal for large load-bearing elements in high-rise buildings such as columns, shear walls, and elevator core walls.

Benefits:

- Enhances the safety and durability of construction projects.

- Maximizes usable space by reducing the size of columns and walls.

LOW-SHRINKAGE CONCRETE

Characteristics:

With an appropriate mix design and special additives, this concrete exhibits significantly lower drying shrinkage compared to standard concrete.

Applications:

Suitable for large, exposed surfaces requiring high-quality finishes.

Benefits:

- Enhances the aesthetics and longevity of structures.

- Reduces repair costs due to drying shrinkage cracks.

HIGH-DURABILITY CONCRETE

Characteristics:

High-durability concrete is developed to minimize the impact of natural corrosive environments and usage-induced corrosion.

Applications:

Used in underground structures, construction projects in or exposed to corrosive environments, storage tanks, treatment tanks, and drainage systems.

Benefits:

Ensures long-term durability of structures, reducing maintenance and repair costs.

MASS CONCRETE

Characteristics:

This concrete is specially designed to minimize heat generation during the cement hydration process.

Applications:

Used for large monolithic foundations and large transfer beam systems that require special construction and curing conditions according to standards.

Benefits:

- Enables quick monolithic construction.

- Reduces cracking due to thermal stress during the early stages of hydration.

- Complies with standard requirements.

BORED PILE CONCRETE - DIAPHRAGM WALL

Characteristics:

This concrete is designed for high workability, maintaining good fluidity, easy to place while ensuring homogeneity.

Applications:

Used for constructing deep foundations such as bored piles and diaphragm walls, suitable for on-site construction methods.

Benefits:

- Enables fast construction.

- Provides dense, monolithic, and uniform concrete.

- Meets standard requirements.

HIGH-RISE BUILDING

SOLUTIONS

READY-MIX MORTAR

High-flow ready-mix mortar used for effective finishing projects.

HIGH-WORKABILITY CONCRETE

Used for beams, columns, and walls with dense reinforcement designs that are difficult to compact during construction.

HIGH-WORKABILITY CONCRETE

Characteristics:

High-workability concrete is easy to place in areas with dense reinforcement and hard-to-reach locations.

Applications:

Used for beams, columns, and walls with dense reinforcement designs that are difficult to compact during construction.

Benefits:

- Facilitates faster construction

- Saves time and labor

HIGH-STRENGTH CONCRETE

Ideal for large load-bearing elements in high-rise buildings such as columns, shear walls, and elevator core walls.

HIGH-STRENGTH CONCRETE

Characteristics:

This product features a high compressive strength of ≥ 60MPa, making it suitable for structural components requiring heavy load-bearing capacity.

Applications:

Ideal for large load-bearing elements in high-rise buildings such as columns, shear walls, and elevator core walls.

Benefits:

- Enhances safety and durability of construction projects.

- Maximizes usable space by reducing the size of columns and walls.

LOW-SHRINKAGE CONCRETE

Suitable for large, exposed surfaces requiring high-quality finishes.

LOW-SHRINKAGE CONCRETE

Characteristics:

With an appropriate mix design and special additives, this concrete exhibits significantly lower drying shrinkage compared to standard concrete.

Applications:

Suitable for large, exposed surfaces requiring high-quality finishes.

Benefits:

- Enhances the aesthetics and longevity of structures.

- Reduces repair costs due to drying shrinkage cracks.

HIGH-DURABILITY CONCRETE

Wastewater treatment tank, aggressive environment.

HIGH-DURABILITY CONCRETE

Characteristics:

High-durability concrete is developed to minimize the impact of natural corrosive environments and usage-induced corrosion.

Applications:

Used in underground structures, construction projects in or exposed to corrosive environments, storage tanks, treatment tanks, and drainage systems.

Benefits:

Ensures long-term durability of structures, reducing maintenance and repair costs.

MASS CONCRETE

Foundation, concrete foundation system

MASS CONCRETE

Characteristics:

This concrete is specially designed to minimize heat generation during the cement hydration process.

Applications:

Used for large monolithic foundations and large transfer beam systems that require special construction and curing conditions according to standards.

Benefits:

- Enables quick monolithic construction.

- Reduces cracking due to thermal stress during the early stages of hydration.

- Complies with standard requirements.

BORED PILE CONCRETE - DIAPHRAGM WALL

Deep foundation: Bored pile - Diaphragm wall

BORED PILE CONCRETE - DIAPHRAGM WALL

Characteristics:

This concrete is designed for high workability, maintaining good fluidity, easy to place while ensuring homogeneity.

Applications:

Used for constructing deep foundations such as bored piles and diaphragm walls, suitable for on-site construction methods.

Benefits:

- Enables fast construction.

- Provides dense, monolithic, and uniform concrete.

- Meets standard requirements.

SUSTAINABLE SOLUTIONS

SUSTAINABLE

SOLUTIONS

LOW CARBON CONCRETE

Characteristics:

Concrete with low embodied carbon.

Applications:

This product meets the emission reduction requirements for materials used in sustainable construction projects and green buildings.

Benefits:

Meets requirements for reducing carbon emissions and greenhouse gases; Contributes to green building certification points.

PERVIOUS CONCRETE

Characteristics:

Concrete allows natural water infiltration through its surface.

Applications:

Parks, playgrounds, parking lots, walkways, and internal roads.

Benefits:

- Recharges natural groundwater.

- Reduces surface drainage pressure in campuses and urban areas.

- Provides solutions for green constructions.

CONTACT INFORMATION

HEAD OFFICE

TERRA YAMAKEN CONCRETE JOINT STOCK COMPANY - SONG THAN 3 CONCRETE BATCHING PLANT

Address: Lot CN2, Song Than 3 Industrial Park, Binh Duong Ward, Ho Chi Minh City, Vietnam

REPRESENTATIVE OFFICE

TERRA YAMAKEN CONCRETE JOINT STOCK COMPANY - CAT LAI CONCRETE BATCHING PLANT

Address: Km No. 7, Nguyen Thi Dinh Street, Cat Lai Ward, Ho Chi Minh City, Vietnam

CONTACT US

Hotline: (+84) 0274 386 1871

Email: info@terrayamaken.com

TERRA YAMAKEN CONCRETE JOINT STOCK COMPANY © 2025.All rights reserved

TERRA YAMAKEN © 2024.

All rights reserved.Powered by SaoKim Digial