Table of Contents

ToggleSelf-Compacting Concrete (SCC) is a significant advancement in the construction industry, clearly defined in the Vietnamese standard TCVN 12209:2018. SCC is a type of concrete that can flow and consolidate under its own weight without the need for mechanical vibration. It is especially capable of filling formwork even in the presence of dense reinforcement, while maintaining high homogeneity.

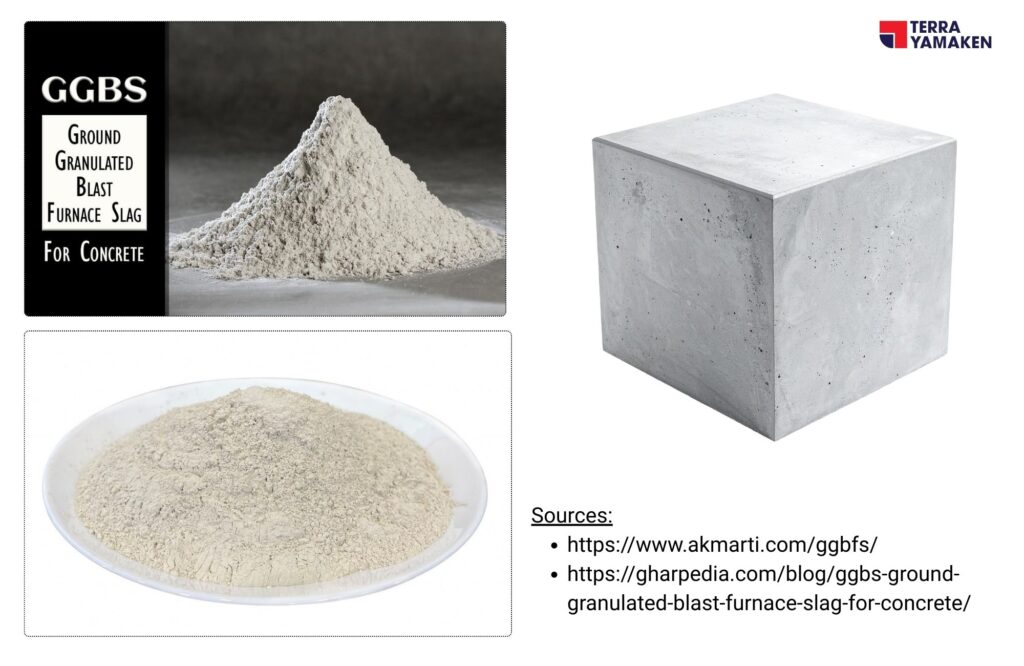

To achieve these superior properties, SCC requires the use of materials such as Portland cement, aggregates conforming to TCVN 7570:2006, and both mineral and chemical admixtures in accordance with relevant standards. The testing and evaluation procedures for SCC are also specified in detail to ensure the quality and performance of the concrete in practical applications.

These technical requirements and testing methods not only optimize the performance of SCC but also expand its applicability in complex construction projects.

Definition of Self-compacting concrete (SCC)

Self-Compacting Concrete (SCC) is a type of concrete that, in its fresh state, can flow and consolidate under its own weight without the need for mechanical vibration. It is capable of filling formwork—even in the presence of dense reinforcement—while maintaining high homogeneity.

Technical requirements

- Cement: Use Portland cement and blended Portland cement that comply with current applicable standards.

- Aggregates: Both coarse and fine aggregates must conform to TCVN 7570:2006.

- Mineral Admixtures: Use silica fume, finely ground rice husk ash, and other mineral admixtures in accordance with relevant standards.

- Chemical Admixtures: Use high-range water-reducing admixtures (superplasticizers) and viscosity-modifying admixtures, compliant with applicable standards.

- Mixing Water: Water used in SCC is generally the same as that used in conventional concrete, but in lower dosages due to the use of admixtures that reduce water demand. In Vietnam, mixing water must comply with TCVN 4506:2012.

Testing and evaluation procedures for SCC according to TCVN 12209:2018

- Sampling: Fresh SCC samples must be taken in accordance with TCVN 3105:1993. When casting specimens for testing physical and mechanical properties, the concrete must be poured continuously to the full height of the mold without any mechanical consolidation

- Flow Spread and Flow Time Determination: This method evaluates the filling ability of SCC.

– Flow spread indicates the free, unrestricted deformation capability of the mix.

– Flow time reflects the rate of deformation within a defined spread distance.

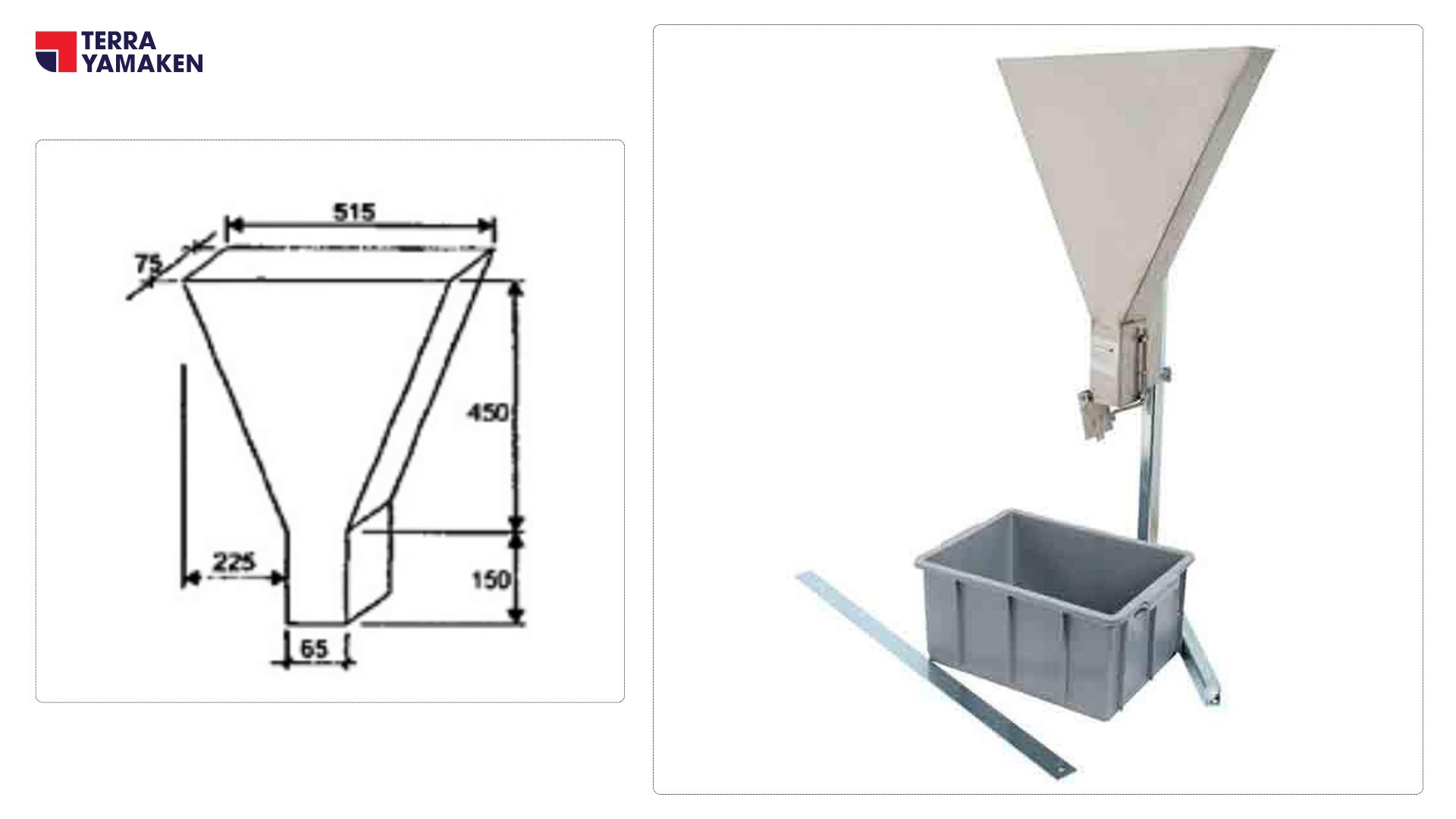

- Determination of V-Funnel Flow Time: The V-funnel flow time, denoted as tv, is the duration required for a specified volume of Self-Compacting Concrete (SCC) to pass completely through a narrow opening in the V-funnel apparatus. This test indicates the filling ability of the SCC mix under conditions where blocking and/or segregation do not occur.

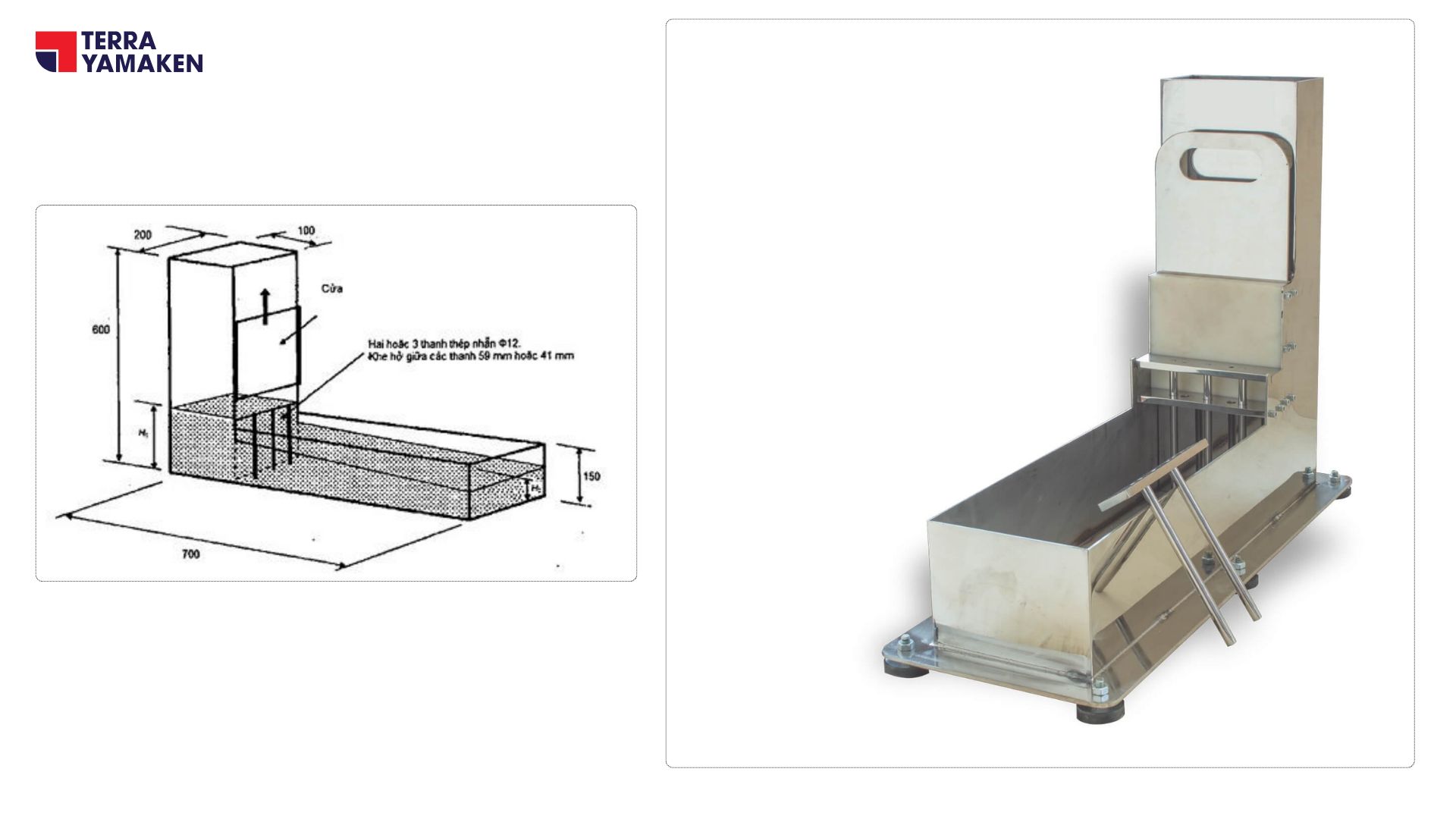

- Determination of Passing Ability Through the L-Box: This method is used to evaluate the passing ability of Self-Compacting Concrete (SCC) through confined spaces. The test involves measuring the height of the SCC after it flows through a set of reinforcing bars arranged at a specified spacing within the L-box apparatus. The resulting height indicates the mix’s ability to pass through narrow gaps without blocking, reflecting its suitability for use in heavily reinforced structural elements.

- Determination of Passing Ability Using the J-Ring Test: The J-Ring test is an alternative method for evaluating the passing ability of Self-Compacting Concrete (SCC). The J-Ring flow spread reflects the restricted deformability of the SCC mix due to potential blocking effects caused by reinforcing bars.

- Determination of Segregation Resistance: This method assesses the segregation resistance of SCC by measuring the amount of mix that passes through a 5 mm sieve. If the SCC has poor resistance to segregation, the paste or mortar component will easily flow through the sieve, indicating a tendency for separation.

- Determination of Other Properties of Fresh SCC: When required to evaluate additional properties such as temperature, air content, setting time, etc., the corresponding test methods for conventional heavy-weight concrete are applied. However, no mechanical vibration or compaction is permitted during specimen preparation for SCC.

These principles ensure that testing is conducted accurately and consistently, allowing for reliable assessment of SCC characteristics under practical conditions.

Applications of Self-Compacting concrete in concrete and reinforced concrete structures

Self-Compacting Concrete (SCC) is widely used in both cast-in-place and precast concrete structures. It is particularly suitable for elements with dense reinforcement or complex geometries. Appendix A (informative) of TCVN 12209:2018 provides recommendations for appropriate applications based on specific performance criteria of SCC mixes. Interpretation of Appendix A (Informative) in TCVN 12209:2018

SCC is classified based on several performance indicators:

- Flowability: SF1, SF2, SF3 (based on flow spread diameter)

- Material adjustment effects: PT (plastic), VT (viscous), CT (cohesive)

- Viscosity: VS1, VS2

- Passing ability: PL1, PL2

- Segregation resistance: SR1, SR2

These classifications help guide the selection and application of SCC mixes for specific structural and construction requirements.

A.1 Slump-Flow (SF) Classification

| Class | Recommended Applications |

|---|---|

| SF1 | – Concrete structures with little or no reinforcement, cast from above (e.g., slabs). – Shotcrete applications (e.g., tunnel construction). – Structures with narrow cross-sections to avoid long horizontal flow paths (e.g., piles, deep foundations). |

| SF2 | – General structural elements (e.g., walls, columns). |

| SF3 | – Vertical elements with dense reinforcement, complex geometry, or requiring bottom-up formwork filling. – Produces better surface finish than SF2 but is more prone to segregation. – Typically uses aggregates with Dmax < 20 mm. – If slump-flow > 850 mm, segregation control is critical and Dmax < 10 mm is recommended. |

A.2 Viscosity (VS/VF) Classification

| Class | Recommended Applications |

|---|---|

| VS1 / VF1 | – Structures with dense reinforcement and high surface finish requirements. – Mixes are more susceptible to bleeding and segregation. |

| VS2 / VF2 | – Used to reduce formwork pressure and improve segregation resistance. – May negatively affect surface finish (e.g., air voids) and is sensitive to cold joints or delays between pours. |

A.3 Passing Ability Classification

| Class | Recommended Applications |

|---|---|

| PL1 / PJ1 | – Structures with gaps between reinforcement ranging from 80 mm to 100 mm (e.g., residential buildings, vertical elements). |

| PL2 / PJ2 | – Structures with tighter reinforcement spacing of 60 mm to 80 mm (e.g., civil engineering works). |

A.4 Segregation Resistance Classification

| Class | Recommended Applications |

|---|---|

| SR1 | – Thin slabs and vertical elements with flow path < 5 m and gap > 80 mm. |

| SR2 | – Vertical elements with flow path ≥ 5 m and gap > 80 mm. – Also applicable to tall vertical elements with gap < 80 mm if flow path < 5 m. – If flow path exceeds 5 m, the SR rating should be reduced by 10% from the standard level. – For structures requiring high strength and surface quality, SR2 or a suitably specified SR class should be used. |

Conclusion

Self-Compacting Concrete (SCC) has proven to be a vital material in modern construction, especially for elements with dense reinforcement or complex geometries. The Vietnamese standard TCVN 12209:2018 provides a clear regulatory framework for the production and use of SCC, along with detailed recommendations for its application based on specific performance criteria.

Thanks to its ability to flow and consolidate without vibration, SCC reduces labor and construction time, while enhancing surface quality and durability. With ongoing advancements in construction materials and technology, SCC is expected to remain a top choice for technically demanding and economically efficient projects. Strict adherence to technical standards ensures that SCC performs optimally under all usage conditions.

Related posts

- Practical Guidelines for Mass Concrete Construction According to TCVN 9341:2012

- Understanding the Workability of Fresh Concrete and Slump Loss in High-Rise building

- Risk Assessment and Technical Solutions for Common Types of Concrete Cracks

- Understanding Plastic Shrinkage Cracking in Concrete: Causes and Mitigation Strategies

- What is Fresh Concrete? The Role of Fresh Concrete in the Construction Industry

Keywords:

- self-compacting concrete pdf

- self-compacting concrete mix design

- self compacting concrete test

- self compacting concrete vs normal concrete

- disadvantages of self compacting concrete

- self compacting concrete price

- self compacting concrete ingredients

- self-compacting concrete advantages and disadvantages

- self-consolidating concrete

Tài liệu tham khảo: