Table of Contents

ToggleDuring the construction and service life of reinforced concrete structures, various types of cracks frequently appear, affecting durability, aesthetics, and structural longevity. The five most common types include: plastic shrinkage cracks, plastic settlement cracks, drying shrinkage, structural cracks, and corrosion cracks. Accurately identifying their causes and timing, along with applying appropriate preventive measures, is key to ensuring long-term quality and stability of the structure.

1. Non-Structural Cracks:

1.1 Plastic Shrinkage Cracks in Concrete

Time of Occurrence: Plastic shrinkage cracks occur shortly after concrete placement, during the initial hours when the concrete is still in its plastic state. These cracks develop before the concrete has set and gained sufficient strength to resist surface shrinkage.

Main Causes: The primary cause of plastic shrinkage cracks is the rapid evaporation of moisture from the concrete surface. This is often due to environmental conditions such as high temperatures, low humidity, and strong winds, which increase the rate of evaporation. When evaporation outpaces the rate at which bleed water can rise to the surface, the surface dries and shrinks, leading to cracking. The tensile stresses induced by this rapid drying exceed the tensile strength of the fresh concrete, resulting in cracks.

Prevention Measures: To mitigate plastic shrinkage cracks, several preventive measures can be implemented:

- Job Planning: Ensure efficient scheduling to avoid delays in concrete placement and finishing.

- Environmental Control: Use windbreaks and sunshades to shield the concrete surface from direct wind and sunlight, reducing evaporation rates.

- Surface Moisture Management: Dampen the sub-base before placing concrete to minimize water absorption from the mix, but avoid leaving standing water. To minimize moisture loss and prevent plastic shrinkage cracking, evaporation retardants such as aliphatic alcohols can be applied immediately after screeding. These form a temporary film on the concrete surface, reducing the rate of water evaporation during the critical early hours. For enhanced and longer-lasting protection, a curing compound like Sika® Antisol® E, which is paraffin-based, may be used. This product forms a durable membrane that effectively seals the surface, preventing water loss and promoting optimal cement hydration. The selection between evaporation retardants and curing compounds depends on site conditions, curing duration, and performance requirements.

- Curing: Initiate curing as soon as possible after finishing, maintaining it for at least 3 days, preferably 7 days, using methods such as plastic sheeting or curing compounds.

Polypropylene Fibres: Adding polypropylene fibres to the mix can enhance tensile strength and reduce the likelihood of plastic shrinkage cracking.

Figure 1 – Plastic Shrinkage Cracks in Concrete

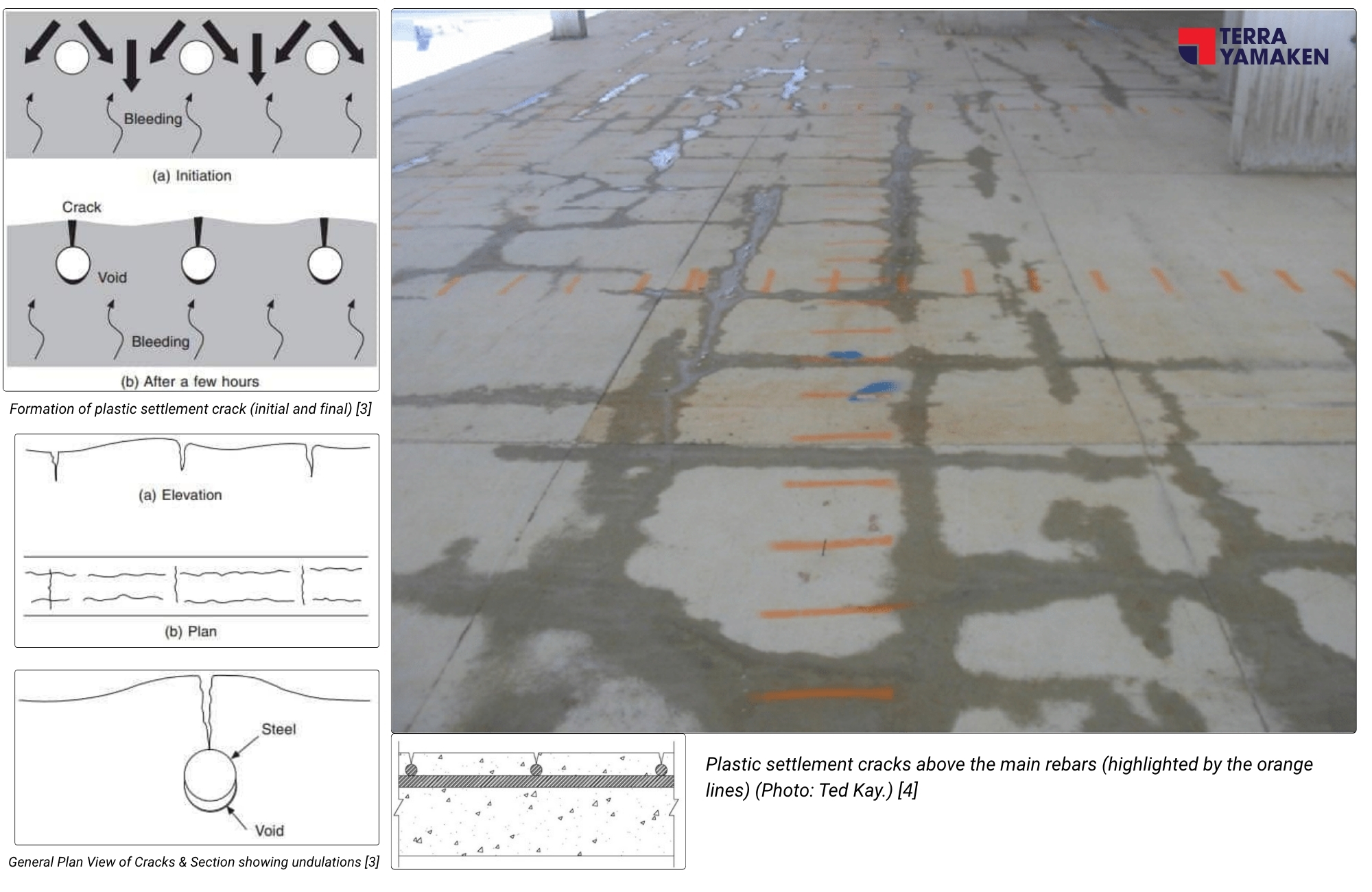

1.2 Plastic Settlement Cracks in Concrete

Time of Occurrence: Plastic settlement cracks occur shortly after the concrete is placed, typically during the initial setting phase. These cracks develop as the concrete settles under its weight, often before it has fully hardened.

Main Causes: The primary cause of plastic settlement cracks is the differential settlement of concrete over embedded objects such as reinforcing mesh or pipework. This often results from inadequate compaction, which fails to eliminate air pockets and ensure uniform density throughout the concrete mass. As the concrete settles, it is restrained by these embedded objects, leading to cracks that appear parallel to them. Excessive water in the mix can exacerbate this issue by increasing settlement.

Prevention Measures: To prevent plastic settlement cracks, several measures can be implemented:

- Adequate Compaction: Ensure thorough compaction of the concrete using appropriate methods such as poker vibrators to expel entrapped air and achieve uniform density. This is crucial over deep beams and around reinforcement.

- Proper Mix Design: Avoid using a mix with excessive water content, which can increase settlement. Ensure the mix is designed to minimize bleeding and segregation.

- Revibration: In cases where there is more than a 300-mm depth of concrete below top bars, revibrate the surface to close up any potential cracks and ensure proper settlement.

- Formwork Stability: Ensure all formwork is stable and capable of withstanding expected loads without shifting, which can contribute to uneven settlement.

Figure 2 – Plastic Settlement Cracks in Concrete [3], [4]

1.3 Drying Shrinkage in Concrete

Drying shrinkage in concrete is a time-dependent volumetric contraction that begins immediately after the concrete has hardened and continues over several weeks to months. Early-age shrinkage cracks typically manifest between the 5th and 7th day, particularly in unrestrained or thin structural elements such as slabs and walls. Approximately 70–80% of the total shrinkage occurs within the first year of service life. This phenomenon is exacerbated under conditions of inadequate curing and high evaporation rates.

The magnitude of drying shrinkage is influenced by several factors, including the degree of restraint imposed by adjacent structural components, the tensile strength of the concrete matrix, and its modulus of elasticity. Under typical conditions, drying shrinkage values range from 0.55 mm to 1.00 mm per meter, depending on mix design, environmental exposure, and member geometry.

Main Causes: Drying shrinkage results from the loss of moisture from hardened concrete, leading to a reduction in volume. The primary driver is the water content in the mix—each 1% increase in water can raise shrinkage by about 2%. Other contributing factors include:

- High paste volume and low aggregate content, which reduce internal restraint and increase shrinkage potential.

- Aggregate properties, such as type, grading, and size. Well-graded aggregates with minimal fines and a sand equivalent value of at least 80% help reduce shrinkage. Larger aggregates provide better elastic restraint to the paste.

- Environmental conditions, particularly low relative humidity and high drying rates, accelerate moisture loss.

- Concrete member geometry, where thinner or smaller sections dry faster and shrink more.

- Restraint from structural elements, such as foundations, adjacent components, or embedded reinforcement, which restrict free movement and induce tensile stresses. Given concrete’s low tensile strength, these stresses often lead to cracking.

Preventive Measures: While it is difficult to eliminate drying shrinkage, several strategies can significantly reduce its impact:

- Optimized Mix Design:

– Use the lowest practical water content and maintain a low water-to-cement ratio.

– Avoid oversanded mixes and maximize the use of large, well-graded aggregates.

– Select slow-hydrating cements to reduce early-age shrinkage. - Structural and Construction Techniques:

– Incorporate control and isolation joints to accommodate shrinkage movement and reduce stress concentrations.

– Use low-slump concrete (≤100 mm) to limit water content and shrinkage.

– Consider shrinkage-compensating admixtures, post-tensioning, or vacuum dewatering to enhance shrinkage control. - Curing and Environmental Management:

– Implement effective curing practices, such as continuous wet curing or curing compounds, to maintain surface moisture and slow drying.

– Protect concrete from rapid moisture loss due to wind, sun, or heat, especially in the early stages.

Understanding the interaction between material properties, environmental exposure, and structural design is essential for predicting and mitigating drying shrinkage. By applying these preventive measures, engineers can significantly enhance the durability and performance of concrete structures, reducing the risk of cracking and long-term deterioration.

Figure 3 – Drying Shrinkage Cracks in Concrete – Source: https://mastercivilengineer.com/what-is-drying-shrinkage-its-occurrence-causes-and-preventive-measures/ [5]

2. Structural Cracks:

2.1 Load-induced structural cracks

Time of Occurrence: Structural cracks in concrete typically occur when the structure is subjected to loads that exceed its design capacity. These cracks can develop at any stage of the structure’s life, from early construction phases to years after completion, depending on the load conditions.

Main Causes: The primary cause of structural cracks is the application of loads that generate tensile stresses beyond the concrete’s tensile strength. Concrete inherently has high compressive strength but low tensile strength, making it susceptible to cracking under tension. Factors contributing to these excessive loads include design errors, unexpected load increases, inadequate reinforcement, or changes in use that were not accounted for in the original design.

Prevention Measures: To prevent structural cracks, several measures should be considered:

- Accurate Design: Ensure that the design accounts for all potential loads, including live loads, dead loads, and environmental factors. Engage a qualified structural engineer to verify calculations and assumptions.

- Adequate Reinforcement: Use appropriate reinforcement to enhance the tensile capacity of the concrete. Proper placement and anchoring of reinforcement bars are crucial to prevent displacement during concrete placement.

Quality Control: Implement strict quality control measures during construction to ensure that materials and workmanship meet design specifications. This includes proper curing and compaction of concrete. - Regular Inspections: Conduct regular inspections and maintenance to identify and address any signs of distress early. This can prevent minor issues from developing into significant structural problems.

- Load Management: Avoid overloading the structure by adhering to the intended use and load limits specified in the design. Any changes in use or additional loads should be evaluated by a structural engineer.

Figure 4 – Structural cracks in Concrete – Source: RK ENGINEERS. (2024, January 27) – https://www.linkedin.com/pulse/structural-cracks-rk-engineers-jcyuc/ [6]

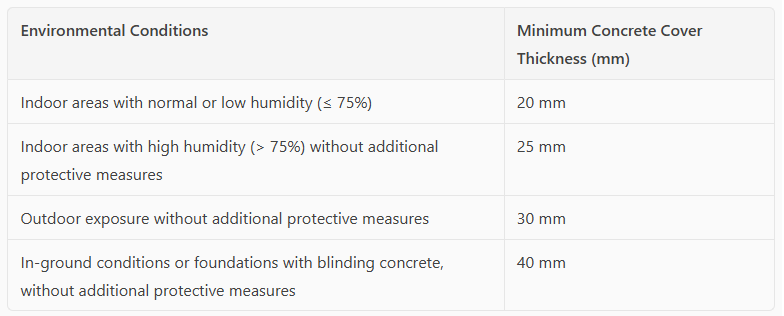

2.2 Corrosion Cracks in Concrete

Time of Occurrence: Corrosion cracks typically develop over time as the embedded steel reinforcement within concrete begins to corrode. This process can occur years after the concrete has been placed, depending on environmental conditions and the quality of the concrete cover.

Main Causes: The primary cause of corrosion cracks is the rusting of steel reinforcement within the concrete. As steel corrodes, it expands, exerting tensile stresses on the surrounding concrete, which leads to cracking. Factors contributing to corrosion include inadequate concrete cover, exposure to chlorides (such as de-icing salts or seawater), carbonation of concrete, and poor-quality concrete that allows moisture and oxygen to reach the steel.

Figure 5 – Corrosion Cracks in Concrete – Image source: Home, C. (2020, February 17). Poured walls, cracks caused by corrosion of reinforcing steel. InterNACHI®️ Forum. [7]

Prevention Measures: To prevent corrosion cracks, several strategies can be implemented:

- Utilize a waterproofing-grade concrete mix specifically designed for low permeability. This involves reducing the water-to-cement ratio to limit porosity and incorporating waterproofing admixtures that enhance resistance to moisture ingress. Proper curing practices must be applied to ensure full hydration and durability. Additionally, controlling temperature during mixing and curing helps prevent thermal cracking, which can create pathways for water. A well-designed mix, combined with correct placement and compaction, ensures a dense concrete matrix that protects embedded reinforcement from corrosion, thereby extending the service life of the structure.

- Adequate Concrete Cover: Ensure sufficient concrete cover over reinforcement to protect it from environmental exposure. The cover should comply with relevant standards and be appropriate for the exposure conditions. To ensure corrosion resistance and long-term durability of reinforced concrete structures, the concrete cover over reinforcement must be designed and constructed following TCVN 5574:2018 – Design of Concrete and Reinforced Concrete Structures, section 10.3.1.2. The cover thickness should be determined based on the role of the reinforcement (main or secondary), the type of structural element (columns, beams, slabs, foundations, walls, etc.), the diameter and type of rebar, and must also comply with environmental exposure requirements as specified in TCVN 12251:2018. According to Table 19 of TCVN 5574:2018, the minimum concrete cover thickness for load-bearing reinforcement (including reinforcement located at the inner edge of hollow ring or box-section elements) is specified as follows:

Figure 6 – Table 19 of TCVN 5574:2018, the minimum concrete cover thickness for load-bearing reinforcement

Complying with the specified concrete cover thickness not only enhances structural durability but also helps mitigate the risk of corrosion-induced cracking and other environmental deterioration.

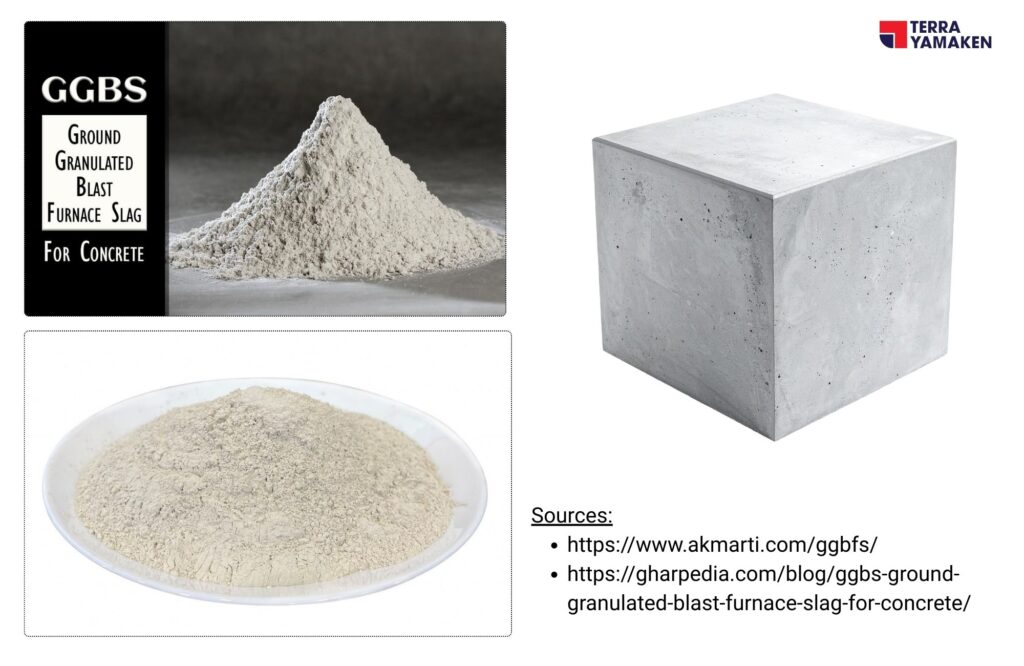

- Quality Concrete Mix: Use a dense, low-permeability concrete mix to minimize moisture ingress. Incorporate supplementary cementitious materials like fly ash or slag to enhance durability.

- Corrosion Inhibitors: Consider using corrosion-inhibiting admixtures in the concrete mix to protect the steel reinforcement.

- Proper Curing: Implement effective curing practices to ensure the concrete achieves its designed strength and durability.

- Regular Inspections: Conduct regular inspections and maintenance to detect early signs of corrosion and address them promptly.

Understanding the characteristics, causes, and preventive measures of common concrete cracks—such as plastic shrinkage cracks, plastic settlement cracks, structural cracks, and corrosion cracks—is essential in the design, construction, and maintenance of reinforced concrete structures. Applying proper techniques and maintaining strict quality control can significantly reduce risks, extend the structural lifespan, and ensure the safety of the structure throughout its service life.

References

- [1] Cement & Concrete Association of Australia. (2000). The housing concrete handbook: A house builders guide to understanding, ordering and handling concrete and other cement-based materials. Cement & Concrete Association of Australia. ISBN 1 876304 10 3.

- [2] Bộ Khoa học và Công nghệ. (2018). TCVN 5574:2018 – Thiết kế kết cấu bê tông và bê tông cốt thép. Hà Nội: Nhà xuất bản Khoa học và Kỹ thuật.

- [3] https://www.facebook.com/TheConstructor. (2013, November 9). Plastic Settlement Cracks in Concrete – Appearance & Prevention Methods. The Constructor. https://theconstructor.org/concrete/plastic-settlement-cracks-concrete/6772/

- [4] Fookes, P. G., & Lee, E. M. (2019). The engineering geology of concrete in hot drylands. Retrieved from https://www.researchgate.net/publication/332063869_The_Engineering_Geology_of_Concrete_in_Hot_Drylands

- [5] Mastercivilengineer. (2021, April 18). What is Drying Shrinkage? Its Occurrence, Causes, and Preventive Measures. Mastercivilengineer. https://mastercivilengineer.com/what-is-drying-shrinkage-its-occurrence-causes-and-preventive-measures [5]

- [6] RK ENGINEERS. (2024, January 27). Structural cracks can develop in buildings and other structures for various reasons, often resulting from a combination of factors. Understanding the below mentioned causes of structural cracks is crucial for implementing effective preventive measures and appropriate repairs. Linkedin.com. https://www.linkedin.com/pulse/structural-cracks-rk-engineers-jcyuc/

- [7] Home, C. (2020, February 17). Poured walls, cracks caused by corrosion of reinforcing steel. InterNACHI®️ Forum. https://forum.nachi.org/t/poured-walls-cracks-caused-by-corrosion-of-reinforcing-steel/161496

Keywords:

- Types of cracks in buildings

- Acceptable cracks in the concrete slab

- Types of cracks in metals

- Types of cracks in concrete walls

- Types of cracks in concrete with pictures

Related Posts