Table of Contents

TogglePlastic shrinkage cracking is a critical issue in concrete construction, occurring when the surface moisture of freshly placed concrete evaporates faster than bleed water can replenish it. This imbalance leads to surface shrinkage while the underlying concrete remains plastic, inducing tensile stresses that cause cracking. [1]

The primary driver of this phenomenon is rapid surface drying, typically under hot, dry, and windy conditions. These environmental factors accelerate evaporation, outpacing the rate of bleed water rise and resulting in cracks before the concrete develops adequate tensile strength. [1]

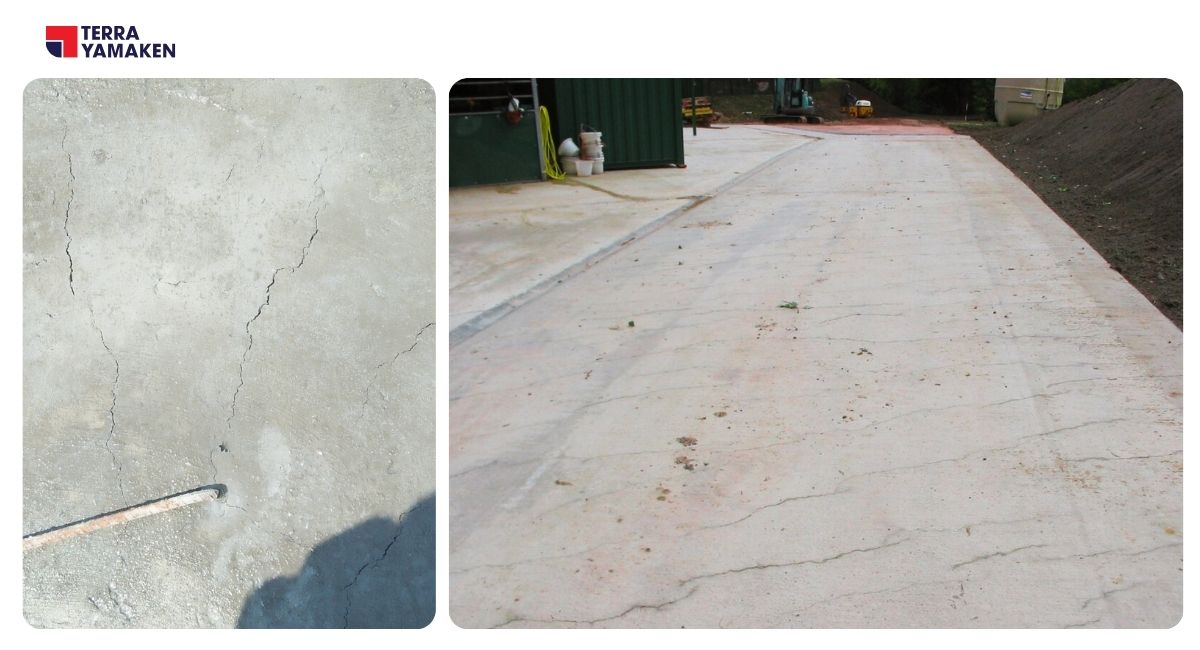

Figure 1: Plastic shrinkage crack on slab [3], [5]

What causes plastic shrinkage cracks? How to prevent plastic shrinkage cracking?

Several factors contribute to the likelihood of plastic shrinkage cracking:

1. Environmental Conditions: High temperatures, low humidity, and strong winds increase evaporation rates, leading to rapid surface drying. [1]

To address this problem, the American Concrete Institute (ACI) provides guidelines and standards to mitigate plastic shrinkage cracks. ACI 305R, “Guide to Hot Weather Concreting,” offers procedures for managing concrete curing in hot weather conditions. It emphasizes the importance of initial curing methods to minimize the risk of plastic shrinkage cracks. These methods include the use of fogging, windbreaks, and shading to control the rate of evaporation.

Evaporation retardants are another effective solution recommended by ACI 308.1-11, “Specification for Curing Concrete.” These retardants form a thin, continuous film over the concrete surface, significantly reducing moisture loss. The application of these retardants should follow the manufacturer’s recommendations to ensure their effectiveness.

Figure 2: Plastic shrinkage crack on slab [3]

2. Concrete Mix Design: High water content in the mix can increase bleeding, but if evaporation outpaces bleeding, it can lead to cracking. The use of certain admixtures can also influence the rate of setting and bleeding. [1]

In concrete mix design, managing water content is crucial to prevent issues such as increased bleeding and potential cracking. High water content in the mix can lead to excessive bleeding, where water rises to the surface. However, if the rate of evaporation surpasses the bleeding rate, it can result in surface cracking. This is particularly problematic in hot, dry, and windy conditions, which accelerate evaporation. To mitigate these issues, the use of chemical admixtures is recommended. These admixtures can modify the setting time and bleeding rate of concrete. For instance, water-reducing admixtures improve workability without increasing water content, thus reducing bleeding and enhancing the concrete’s strength and durability.

3. Placement and Finishing Practices: Delays in finishing operations can allow more time for evaporation, increasing the risk of cracking. Overworking the surface can also exacerbate moisture loss.

In concrete construction, effective placement and finishing practices are crucial to prevent surface cracking. Delays in finishing operations can lead to increased evaporation time, heightening the risk of cracking. This is particularly problematic in hot, dry, and windy conditions, where rapid moisture loss from the surface can occur. Overworking the concrete surface exacerbates this issue by further accelerating moisture loss, which can lead to shrinkage before the concrete has developed sufficient tensile strength.

To mitigate these risks, it is essential to plan the job to avoid delays once the concrete pour has started. Providing shade and windbreaks to work areas can help reduce evaporation rates. Additionally, using a set-retarding admixture can slow down the setting process, allowing more time for proper placement and finishing. It is also advisable to spray the concrete with an evaporation retardant to further control moisture loss. Proper curing practices, such as maintaining a damp surface for at least three days, are vital to ensure the concrete gains strength and reduces the likelihood of cracking. By adhering to these guidelines, construction professionals can achieve a durable and crack-resistant concrete surface.

Figure 3: Plastic shrinkage crack on slab [3]

4. Substrate Conditions: A dry or absorbent sub-base can draw moisture from the concrete, contributing to surface drying. [1]

Substrate conditions play a crucial role in the quality and durability of the final product. A dry or absorbent sub-base can draw moisture from freshly placed concrete, contributing to premature surface drying. This moisture loss can lead to surface shrinkage and cracking before the concrete has developed sufficient tensile strength. To mitigate these issues, it is essential to dampen the sub-base before placing the concrete, ensuring it is moist but without standing water. This practice helps maintain adequate moisture levels in the concrete, reducing the risk of surface drying and subsequent cracking. Additionally, using a vapor barrier can prevent moisture from being drawn into the sub-base, further protecting the concrete from drying out too quickly. Proper planning and execution of substrate preparation are vital to achieving a durable and crack-resistant concrete surface. By addressing substrate conditions, construction professionals can enhance the performance and longevity of concrete structures.

Conclusion

In summary, controlling environmental conditions and employing proper curing techniques are essential to prevent plastic shrinkage cracks in concrete. Adhering to standards such as ACI 305R and ACI 308.1-11 provides valuable guidance for implementing these practices effectively [2]. By following these standards, construction professionals can ensure the durability and integrity of concrete structures. Understanding and addressing factors like temperature, humidity, and wind conditions can significantly reduce the risk of plastic shrinkage cracking, thereby ensuring the durability and aesthetic quality of concrete surfaces. Proper planning and execution of preventive measures are crucial for successful concrete construction, especially in challenging environmental conditions. By integrating these strategies, construction professionals can achieve a durable and crack-resistant concrete surface, maintaining both structural integrity and visual appeal.

Referrals

- Cement & Concrete Association of Australia. (2000). The housing concrete handbook. Cement & Concrete Association of Australia. http://www.concrete.net.au

- American Concrete Institute. (2011). Specification for curing concrete (ACI 308.1-11). Farmington Hills, MI: American Concrete Institute. ISBN 978-0-87031-439-1.

- Jha, A. (2019, April 2). Figure 1: Plastic shrinkage crack on slab Figure 2: Shrinkage crack on slab One of the most frequent complaint that is received in the residential house construction is plastic shrinkage crack. The person complains that crack is seen in concrete when they go for curing the next day after concreting. Linkedin.com. https://www.linkedin.com/pulse/plastic-shrinkage-cracks-concrete-abhishek-jha/

- Quality, G. (2020, July 10). Concrete Shrinkage: What Is It, and How Can It Be Prevented? G3 Quality. https://www.g3quality.com/concrete-shrinkage-what-is-it-and-how-can-it-be-prevented/

- jonnyhough. (2025, July 8). Plastic shrinkage cracks | Concrete Society. Concrete Society. https://www.concrete.org.uk/fingertips/plastic-shrinkage-cracks/

Keywords:

- Plastic shrinkage Cracking

- Plastic shrinkage cracking concrete

- Plastic shrinkage and drying shrinkage

- How to repair plastic shrinkage cracks in concrete

- Plastic shrinkage meaning

- How to prevent plastic shrinkage cracks

- Plastic shrinkage chart