Table of Contents

ToggleFly Ash (Tro bay) is a fine-grained byproduct generated from the combustion of pulverized coal in thermal power plants. Chemically, fly ash consists primarily of silicate glass containing silica, alumina, iron oxides, and calcium oxides. It is classified as Class F (low calcium content) or Class C (higher calcium content) according to ASTM C618 [2],[3].

According to TCVN 10302:2014, fly ash is defined as the fine dust collected from the flue gas dust collection system of thermal power plants during coal combustion. This standard applies to fly ash used in concrete, masonry mortar, and cement.

Classification According to TCVN 10302:2014

By Chemical Composition:

- Acidic Fly Ash (F): Calcium oxide (CaO) content ≤ 10%.

- Basic Fly Ash (C): Calcium oxide (CaO) content > 10%.

By Intended Use:

- For concrete and masonry mortar (designated as a, b, c, d depending on application).

- For cement (designated as Xm).

Examples:

- Fa – Acidic fly ash for reinforced concrete.

- CXm – Basic fly ash for cement production.

Application in Concrete

In referenced studies, fly ash is consistently used as a Supplementary Cementitious Material (SCM) and a pozzolanic material in concrete mix designs, with:

- Typical replacement level: Approximately 10–40% of the total binder mass replacing Portland cement [4],[5].

- High-Volume Fly Ash (HVFA): ≥ 50% of the total binder mass. Any concrete containing more than 50% fly ash by mass of total cementitious materials is classified as HVFA concrete [6].

In concrete, the amorphous silica and alumina in fly ash react with Ca(OH)₂ produced during Portland cement hydration to form additional calcium silicate hydrate (C‑S‑H) and other hydration products. The fine spherical particles improve packing density and act as micro-fillers in the cement paste and the interfacial transition zone [4],[7],[8].

Technical Requirements According to TCVN 10302:2014

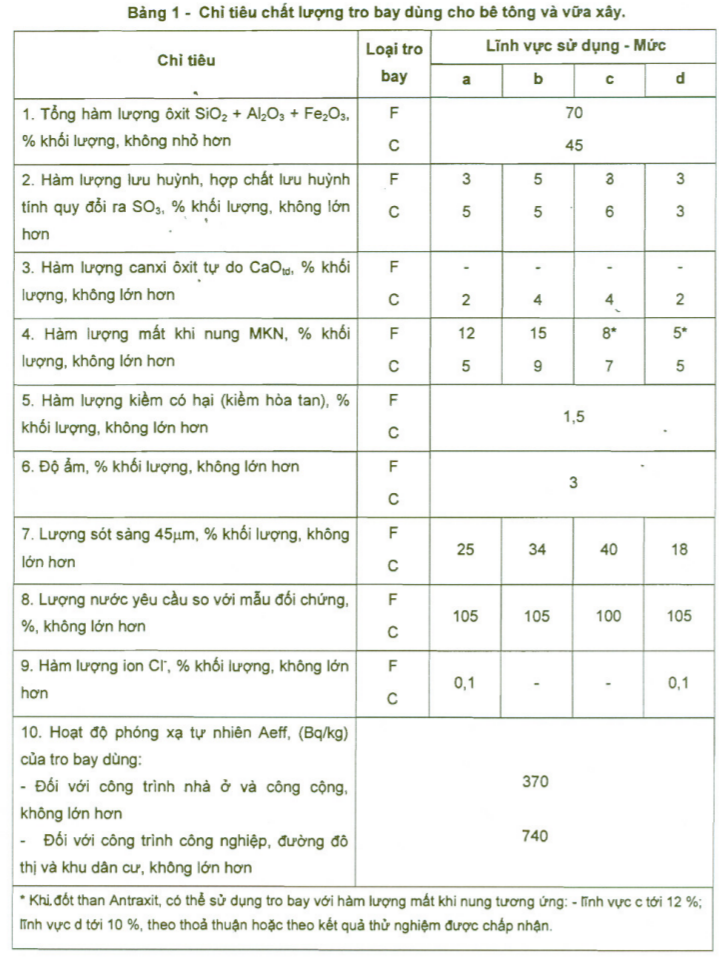

Figure 1 – Quality Criteria for Concrete and Masonry Mortar (Table 1, Section 5.1 – TCVN 10302:2014)

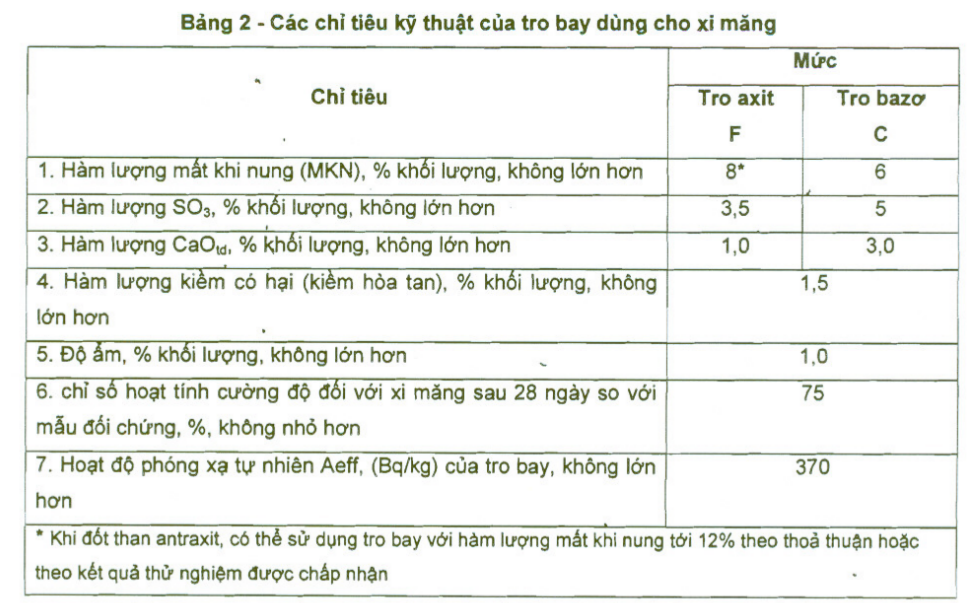

Figure 2 – Technical Requirements for Fly Ash Used in Cement (Table 2, Section 5.2 – TCVN 10302:2014)

Purpose of Using Fly Ash in Concrete

Partial Replacement of Portland Cement

Fly ash is used to partially replace Portland cement to reduce cement consumption, material costs, and the environmental burden associated with cement production [4],[6],[9]. Typical replacement levels include:

- 10–40% Class F fly ash in conventional concrete [4].

- 35–55% (≥50%) in High-Volume Fly Ash (HVFA) concrete [6],[10].

Utilizing Pozzolanic Activity for Strength and Long-Term Durability

Amorphous silica in Class F fly ash reacts with Ca(OH)₂ to form additional C‑S‑H, resulting in continued strength gain beyond 28 days and a denser microstructure [4],[7],[8].

- Concrete with 30–40% fly ash shows lower 28-day strength but significant development up to 180 days (≈82–88% of control) [4].

- HVFA mixes (35–55%) achieve superior 91-day strength, especially with fine fly ash [10].

Controlling Heat of Hydration and Thermal Cracking (Mass Concrete)

Replacing cement with high levels of fly ash significantly reduces adiabatic temperature rise and peak internal temperatures in mass concrete elements [6],[10],[11].

- HVFA (35–55%) lowers peak adiabatic temperature by 73–89% compared to conventional concrete.

- Core temperature in a 1200 × 1200 × 1200 mm mock-up decreases by 68–83%, improving thermal cracking resistance [10],[11].

Improving Fresh Concrete Properties and Workability

The spherical particles of fly ash act as “ball bearings,” enhancing flowability and reducing water demand [12].

- At 25% replacement, slump increases by 18–22%, and flow spread by 8–9% compared to control [12].

- HVFA leverages this effect to maintain workability at low water-to-binder ratios [6],[13].

Enhancing Durability in Aggressive Environments

Fly ash refines pore structure, reduces permeability, and improves resistance to chloride ingress, sulfate attack, freeze–thaw cycles, and alkali–silica reaction (ASR) [4],[14],[15].

Permissible Standards / Classification

Fly ash, when used as a reactive mineral admixture in concrete, is governed by:

- Vietnam Standard TCVN 10302:2014 – Reactive Mineral Admixture – Fly Ash for Use in Concrete, Masonry Mortar, and Cement – Ministry of Science and Technology (2014).

- ASTM C618 – Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete, which forms the basis for classifying fly ash as Class F [2]. Long-term durability studies typically use Class F fly ash per ASTM C618 [4].

- Concrete mix design generally follows ACI 211 – Guide for Selecting Proportions for High-Strength Concrete with Portland Cement and Fly Ash [3],[16].

- Other relevant ASTM standards:

- ASTM C39 – Compressive Strength of Cylindrical Concrete Specimens

- ASTM C1202 – Rapid Chloride Permeability Test

- ASTM C204 – Fineness by Air Permeability (Blaine) [4],[10],[17].

Benefits of Fly Ash in Concrete

1. Improved Workability and Reduced Water Demand

The spherical particle shape and relatively low water demand of fly ash enhance concrete workability. In high-strength concrete with manufactured sand (MSC) and natural sand concrete (NSC), slump and slump-flow increase with higher fly ash replacement. At 25% fly ash, MSC shows slump and flow increases of 22.2% and 9.4%, while NSC shows 18.4% and 8.2% compared to mixes without fly ash [12].

HVFA mixes also exhibit improved workability due to the “ball-bearing” effect and optimized particle packing, allowing low water-to-binder ratios while maintaining required slump [6],[13].

TCVN 10302:2014 requirements for fly ash in concrete and mortar:

- Water demand relative to control: ≤105%

- Fineness: residue on 45 µm sieve ≤25–40%

- Moisture content: ≤3%

This ensures that fly ash maintains good workability without significantly increasing water demand.

2. Enhanced Long-Term Strength Development

Studies on Class F fly ash concrete (replacement 0–40%, w/b = 0.35) show that 7-day compressive strength decreases as fly ash content increases:

- 10%, 20%, 30%, and 40% fly ash achieve approx. 86%, 74%, 56%, and 51% of control strength [4].

- However, strength continues to develop significantly up to 180 days and 1 year. After one year, mixes with 10–40% fly ash reach 88%, 82%, 87%, and 83% of control strength [4].

- HVFA mixes (35–55%) show reduced early strength but superior 91-day strength, especially with fine fly ash (e.g., 55% replacement achieving 54.2 MPa) [10].

- TCVN 10302:2014 requires a strength activity index ≥75% at 28 days, aligning with the long-term pozzolanic mechanism.

3. Reduced Permeability, Sorptivity, and Capillary Pore Volume

Capillary pore volume (VPV) decreases with higher fly ash content:

- At 28 days, VPV ranges 7.8–9.2%; at 180 days, VPV drops to 6.6%, 6.0%, 5.8%, 5.2%, and 5.1% for 0, 10, 20, 30, and 40% fly ash [4].

- Sorptivity also decrease, At 28 days: 0.097, 0.088, 0.081, 0.073, 0.068 mm·min⁻⁰·⁵ for 0–40% fly ash (100%, 91%, 84%, 75%, 70% of control) [4].

- SEM images confirm pozzolanic reaction and pore refinement over time [4],[8].

4. Improved Chloride Resistance and ASR Mitigation

ASTM C1202 tests show reduced chloride ion penetration:

- At 28 days, 10–40% fly ash reduces charge passed to 93%, 73%, 52%, and 47% of control [4].

- At 180 days, mixes with 20–40% fly ash fall into “very low” chloride permeability category [4].

- Class F fly ash is most effective due to high fineness and alkali-binding capacity, reducing ASR risk [15],[18].

TCVN 10302:2014 limits soluble alkalis to ≤1.5% and chloride ions to ≤0.1%.

5. Reduced Drying Shrinkage and Cracking

Replacing cement with fly ash lowers free lime and hydration rate, reducing shrinkage:

- 10–40% fly ash reduces shrinkage to 91%, 84%, 75%, and 70% of control at 180 days [4].

- 50% replacement can reduce shrinkage by ~30% [14].

- In mass concrete, HVFA (35–55%) reduces peak adiabatic temperature and thermal gradients, improving crack resistance [10],[11].

6. Improved Sulfate Resistance, Wind Erosion, and Freeze–Thaw Durability

In high-strength MSC and NSC exposed to combined sulfate attack, wind erosion, and freeze–thaw cycles, 10–15% fly ash provides optimal durability [12].

7. Lower Carbon Footprint and Enhanced Sustainability

- Cement production accounts for ~7% of global greenhouse gas emissions [9].

- Replacing 50% cement with fly ash can reduce CO₂ emissions by ≈42% and production costs by ≈21% [19].

- Fly ash utilization promotes waste reduction and sustainable infrastructure [1],[6],[20].

8. Compatibility with Structural Design Practices

- The relationship between elastic modulus and compressive strength in HVFA concrete is similar to conventional concrete, allowing use of existing design formulas [10].

- HVFA achieves long-term strength equal to or greater than Portland cement concrete while reducing thermal cracking in mass elements [6],[11],[21].

Conclusion

Using fly ash as a reactive mineral admixture in concrete is a strategic solution to meet technical, economic, and environmental requirements in modern construction. With its pozzolanic properties and spherical particle effect, fly ash improves workability, reduces water demand, enhances durability, lowers permeability, mitigates shrinkage, and increases resistance to aggressive environments.

International standards (ASTM C618, ACI) and TCVN 10302:2014 provide clear frameworks for classification, chemical requirements, fineness, and activity indices, ensuring compatibility with structural design. Beyond technical benefits, fly ash substitution reduces CO₂ emissions, optimizes costs, and supports sustainable development—an essential direction for high-performance concrete and green infrastructure in the future.

Ralated posts:

- Crushed sand (artificial sand) for concrete production | Key Technical Requirements

- Pressure Method for Determining Air Content in Fresh Concrete Mixture According to National Standard TCVN 3111:2022

- The Difference Between Air Content and Bugholes in Concrete?

Keywords:

- Fly ash concrete

- Fly ash bricks

- Fly ash radioactive

- Fly ash uses

- Fly ash composition

- Fly Ash for sale

- Fly ash price

- Fly ash cement

Referral:

[1] Ondova, M., Stevulova, N., & Estokova, A. (2012). The study of the properties of fly ash based concrete composites with various chemical admixtures. Procedia Engineering, 42, 1863–1872.

[2] ASTM C618-08. (2008). Standard specification for coal fly ash and raw or calcined natural pozzolan for use in concrete. ASTM International.

[3] ACI Committee 211. (1993). Guide for selecting proportions for high-strength concrete with Portland cement and fly ash (ACI 211). American Concrete Institute.

[4] Saha, A. K. (2018). Effect of class F fly ash on the durability properties of concrete. Sustainable Environment Research, 28, 25–31.

[5] Ondova, M., Stevulova, N., & Zelenakova, E. (2012). Benefits of fly ash utilization in concrete road cover. Journal of Theoretical Foundations of Chemical Engineering.

[6] Crouch, L. K., Hewitt, R., & Byard, B. (High Volume Fly Ash Concrete). High Volume Fly Ash Concrete. Tennessee Technological University.

[7] Chindaprasirt, P., Jaturapitakkul, C., & Sinsiri, T. (2005). Effect of fly ash fineness on compressive strength and pore size of blended cement paste. Cement and Concrete Composites, 27, 425–428.

[8] Saha, A. K., & Sarker, P. K. (2017). Microstructural observation of fly ash concrete (SEM analysis). In A. K. Saha, Effect of class F fly ash on the durability properties of concrete (pp. 28–29). Sustainable Environment Research, 28, 25–31.

[9] Saha, A. K. (2018). Introduction: Cement production, CO₂ emissions, and the role of supplementary cementitious materials. Sustainable Environment Research, 28, 25–31.

[10] Oh, S., Oh, G., Hong, G., & Choi, Y.-C. (2024). Thermomechanical properties of high-volume fly ash concrete for application in mass concrete. Case Studies in Construction Materials, 23, e00825.

[11] Xin, J., Liu, Y., Zhang, G., Wang, Z., Wang, J., Yang, N., & Qiao, Y. (2022). Evaluation of early-age thermal cracking resistance of high w/b, high volume fly ash (HVFA) concrete using a temperature stress testing machine. Case Studies in Construction Materials, 16, e00825

[12] Zhou, H., Wu, X., Han, C., & Wei, Y. (2025). Research on durability and multi-index evaluation of carbon emissions for high-strength concrete with fly ash manufactured sand. Case Studies in Construction Materials, 23, (article number pending).

[13] Obla, K., Hill, R., & Martin, R. (2003). HVFA concrete – An industry perspective. Concrete International, 25(8), 29–34.

[14] Atiş, C. D. (2003). High-volume fly ash concrete with high strength and low drying shrinkage. Journal of Materials in Civil Engineering, 15, 153–158.

[15] Wang, S., Llamazos, E., Baxter, L., & Fonseca, F. (2008). Durability of biomass fly ash concrete: Freezing and thawing and rapid chloride permeability tests. Fuel, 87, 359–364.

[16] ACI Committee 211. (1993). Guide for selecting proportions for high-strength concrete with Portland cement and fly ash (ACI 211). American Concrete Institute.

[17] ASTM C204-16. (2016). Standard test methods for fineness of hydraulic cement by air-permeability apparatus. ASTM International.

[18] Shehata, M. H., Thomas, M. D. A., & Bleszynski, R. F. (1999). The effects of fly ash composition on the chemistry of pore solution in hydrated cement pastes. Cement and Concrete Research, 29, 1915–1920.

[19] Mocharla, I. R., Selvam, R., Govindaraj, V., & Muthu, M. (2022). Performance and life-cycle assessment of high-volume fly ash concrete mixes containing steel slag sand. Construction and Building Materials, 341, 127814.

[20] Ahmaruzzaman, M. (2010). A review on the utilization of fly ash. Progress in Energy and Combustion Science, 36, 327–363.

[21] Langley, W., Carette, G., & Malhotra, V. M. (1989). Structural concrete incorporating high volumes of ASTM Class F fly ash. ACI Materials Journal, 86(5), 507–514.

[22] Bộ Khoa học và Công nghệ. (2014). TCVN 10302:2014 – Phụ gia hoạt tính tro bay dùng cho bê tông, vữa xây và xi măng (Activity admixture – Fly ash for concrete, mortar and cement). Hà Nội: Nhà xuất bản Tiêu chuẩn.