Fresh concrete, commonly referred to as ready-mixed concrete, is a composite material consisting of cement, water, fine and coarse aggregates, and often chemical admixtures. In its initial state, concrete is plastic, allowing it to be molded into various shapes. Its properties at this stage are critical, as they affect handling, placement, compaction, and finishing.

Table of Contents

ToggleWhat is Fresh Concrete?

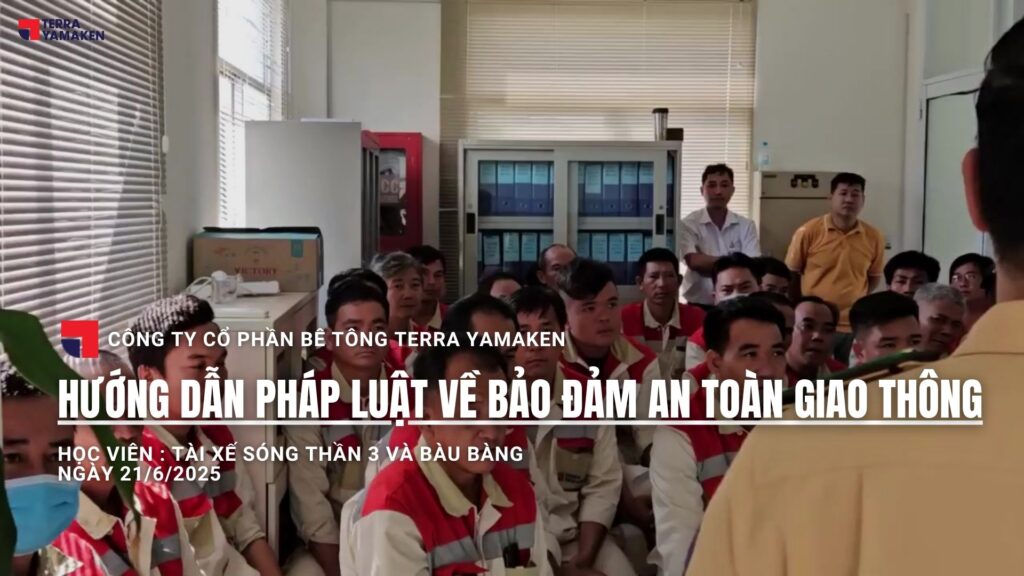

Ready-mixed concrete is produced at a batching plant following a specific mix design and transported to construction sites using truck-mounted transit mixers. This controlled production ensures consistent quality, which is essential for the structural integrity of construction projects, especially large-scale ones where on-site mixing is impractical.

A key property of fresh concrete is workability, defined as the ease with which concrete can be mixed, placed, compacted, and finished without segregation. Workability is commonly assessed using the slump test, which indicates the water content and consistency of the mix. A higher slump value generally means better workability but may also suggest a higher water-cement ratio, which can compromise the strength and durability of hardened concrete.

The water-cement ratio is a critical factor in determining concrete’s performance. A lower ratio enhances strength and durability but may reduce workability. Conversely, increasing water improves workability but weakens the cement paste—similar to how dilution reduces the bonding strength of glue.

To achieve the desired concrete properties, precise measurement and proportioning of materials are essential. Mechanical mixing ensures uniform consistency, and the use of chemical admixtures like plasticizers or superplasticizers can improve workability without increasing water content. These admixtures are especially beneficial in complex formworks or densely reinforced sections.

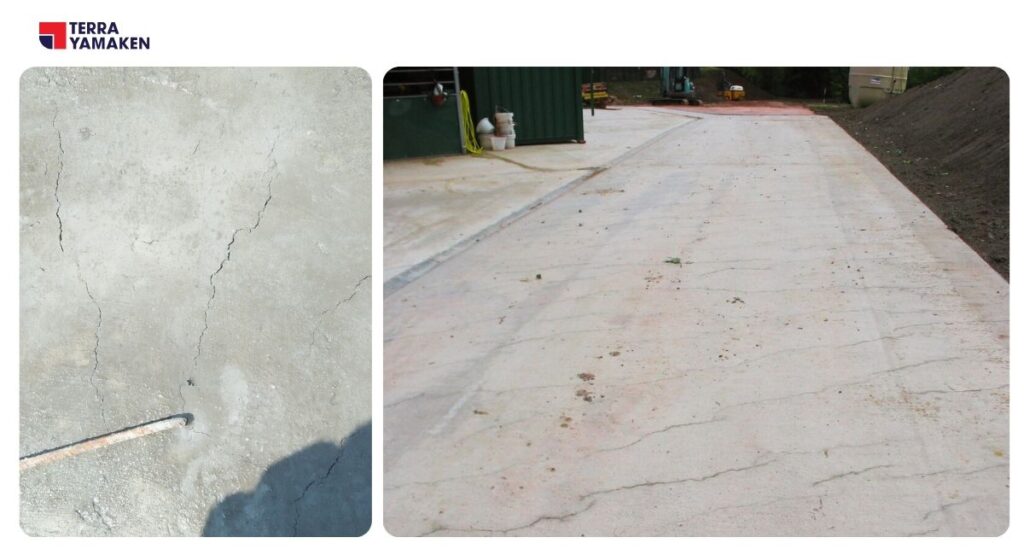

Curing is another vital step, involving the maintenance of adequate moisture, temperature, and time to allow complete hydration of cement particles. Proper curing enhances compressive strength, reduces shrinkage cracking, and improves surface hardness.

In summary, the performance of fresh or ready-mixed concrete depends on the careful selection, proportioning, and handling of its components. Maintaining the specified water-cement ratio, using appropriate admixtures, and ensuring proper curing are essential for achieving optimal strength, durability, and workability in construction applications.

The role of ready-mixed concrete in the construction industry

Ready-mixed concrete plays a pivotal role in the construction industry, offering a versatile and efficient solution for various building needs. This type of concrete is manufactured in a batching plant according to a set recipe and then delivered to a work site by truck-mounted transit mixers. This process ensures that the concrete is of high quality and consistent, which is crucial for the structural integrity of any construction project.

The primary advantage of ready-mixed concrete is its ability to be customized to meet specific project requirements. This customization includes adjustments in the mix design to achieve desired properties such as workability, strength, and durability. The mix can be tailored by altering the proportions of cement, water, aggregates, and admixtures. Admixtures are particularly important as they can enhance the performance of concrete under various conditions. For instance, superplasticizers can increase the fluidity of concrete without adding extra water, which is beneficial in situations where reinforcement is dense or formwork is complex.

Transportation from the batching plant to the construction site is a critical phase in the use of ready-mixed concrete. It must be done efficiently to prevent the initial setting of the concrete before it is placed. The timing of deliveries should be carefully planned to avoid delays that could compromise the quality of the concrete. Once on site, the concrete must be placed and compacted properly to ensure it achieves its full potential strength and durability. Proper compaction eliminates air pockets and ensures that the concrete fully encapsulates any reinforcement.

Curing is another essential step in the process, as it allows the concrete to achieve its designed strength and durability. Curing involves maintaining adequate moisture, temperature, and time to allow the hydration process to continue. This can be achieved through various methods such as covering with wet burlap or plastic sheeting, or applying curing compounds.

The use of ready-mixed concrete also supports sustainable construction practices. By reducing waste and minimizing the need for on-site mixing, it helps lower the environmental impact associated with construction activities. Additionally, ready-mixed concrete can incorporate supplementary cementitious materials like fly ash or slag, which are by-products from other industries, further enhancing its sustainability profile.

In summary, ready-mixed concrete is an indispensable component of modern construction, offering flexibility, efficiency, and sustainability. Its proper use requires careful planning and execution from batching to curing to ensure that it meets the structural and aesthetic requirements of any project.

- The referenced knowledge is from “The Housing Concrete Handbook,” first published in June 2000 by the Cement & Concrete Association of Australia.

- Reference Article: Fresh vs Hard Properties of Concrete | Explained

Keywords:

- Readymade Concrete

- Mix concrete

- Concrete m3

- Order concrete

- How much is concrete

- Buy Concrete

- Fresh concrete

- Ready mix concrete