Table of Contents

ToggleWorkability is a critical technical parameter that reflects the ability of fresh concrete to be transported, pumped, and placed under real construction conditions. In high-rise projects, maintaining adequate flowability and homogeneity of the mix is essential to ensure the integrity and durability of hardened concrete structures. However, during transportation, a common challenge arises: slump loss, which directly affects placement efficiency and overall construction quality.

To better understand this concept, including evaluation methods, classification of plastic concrete mixes (Group D) according to TCVN 9340:2012, and practical solutions for controlling slump loss, we have compiled and presented the following detailed technical content.

Workability of Fresh Concrete

Workability is a key physical-mechanical property of fresh concrete, reflecting its ability to be transported, pumped, and placed under real construction conditions while maintaining homogeneity, cohesion, and resistance to segregation or bleeding.

It represents the mix’s capability to fill formwork of defined shapes under mechanical action (such as vibration or compaction) or under its own weight, while ensuring sufficient stability and flowability.

In pumped concrete applications, workability is a critical criterion for evaluating practical constructability on site. The mix must achieve high workability to ensure continuous flow through the pipeline system and prevent blockages during transportation.

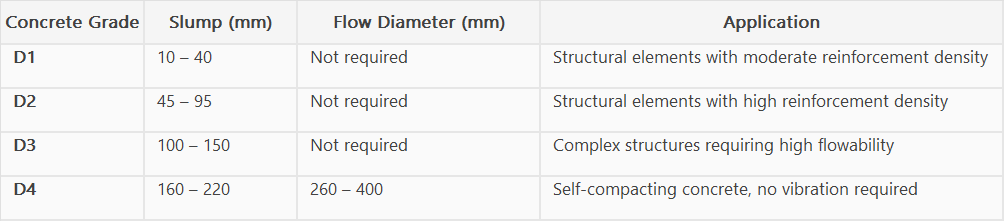

According to Table 1 – Classification of Concrete Mixes by Workability in TCVN 9340:2012, the Plastic Group (Group D) is categorized based on slump value (mm) and flow diameter (mm), providing a standardized framework for assessing and controlling workability in practice.

Excerpt from Table 1 – Classification of Plastic Concrete Mixes (Group D) according to TCVN 9340:2012

The slump test is a standardized method used to evaluate the consistency and workability of fresh concrete, particularly critical in high-rise construction projects. According to EN 12350-2:2019, the slump test is highly sensitive to variations in concrete flowability, with typical slump values ranging from 10 mm to 210 mm. Outside this range, the slump test may no longer be suitable, and alternative testing methods should be considered.

To ensure accuracy, the test should be conducted on-site, verifying that the concrete mix remains within the acceptable tolerance limits and is compatible with the selected construction method.

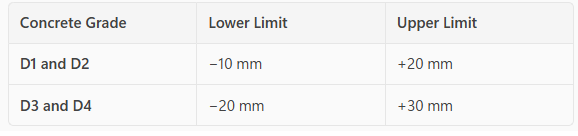

Concrete mixes classified under Group D – Plastic (as per TCVN 9340:2012) are divided into four grades: D1, D2, D3, and D4, based on the slump value (in millimeters) and flow diameter (in millimeters). Workability is considered acceptable when test results fall within the permissible deviation limits specified in Table 3 of the standard.

Excerpt from Table 3 – Permissible Deviations in Slump Test Results for Fresh Concrete Mixes (TCVN 9340:2012)

If the test results do not meet the required criteria, a new sample must be taken and the test repeated from the beginning. If the second test also fails to meet the standard, the concrete mix is considered non-compliant in terms of workability.

Slump Loss Phenomenon

Slump loss is a common phenomenon during the transportation and pumping of concrete, especially in high-rise construction. It directly affects the workability and homogeneity of the mix, which in turn impacts critical construction stages such as placing, compacting, and surface finishing.

Experimental data indicate that slump loss typically occurs at a rate of approximately 25 mm per 300 meters of pipeline length. The primary causes include internal friction, water loss, and mechanical interaction between the concrete mix and the pipe wall during pumping.

To ensure construction quality and operational efficiency, slump loss control must be addressed from the early stages of mix design, transport planning, and site execution. Recommended technical solutions include:

- Predicting slump loss based on pipeline length and elevation.

- Adjusting mix design and using appropriate chemical admixtures to maintain workability at the point of placement.

- Coordinating with the concrete supplier and accredited laboratory to verify, calibrate, and ensure mix quality.

Additionally, slump values should be selected based on the type of structural element and construction method, according to current technical guidelines. Contractors should:

- Estimate expected slump loss, especially when pumping to elevated floors.

- Modify mix proportions or use admixtures to ensure the slump at placement meets the specification.

- Maintain workability without compromising the design compressive strength of the concrete.

Effective slump loss control is a critical factor in ensuring construction quality, minimizing risks of segregation, pipeline blockage, and issues related to density and structural strength after hardening.

Referrals:

[1] Nam. (2025). Tiêu chuẩn: TCVN 9340:2012 – Hỗn hợp bê tông trộn sẵn – Yêu cầu cơ bản đánh giá chất lượng và nghiệm thu. Vsqi.gov.vn. https://tieuchuan.vsqi.gov.vn/tieuchuan/view?sohieu=TCVN+9340%3A2012

[2] Slovenski inštitut za standardizacijo. (2019). SIST EN 12350-2:2019: Testing fresh concrete – Part 2: Slump test. Slovenski inštitut za standardizacijo.

[3] Mix Design and Pumped Concrete. (2015, July 18). Civil Engineering Portal – Biggest Civil Engineering Information Sharing Website. https://www.engineeringcivil.com/mix-design-and-pumped-concrete.html

Keywords

- Workability of concrete

- Factors affecting workability of fresh concrete

- What is workability

- Types of workability of concrete

- High workability concrete means

- Workability and durability of concrete

- Workability test of concrete

- Workability and strength of concrete

Related posts